Have you ever wondered how your car’s power steering works? Or how espresso machines pump out that perfect shot? The answer lies in a clever piece of engineering called the rotary vane pump. These machines move liquids and gases efficiently. They’re used in many industries, from cars to food production. This guide explains what rotary vane pumps are, how they work, their design, and much more. Let’s dive into the world of these fantastic devices.

What Is a Rotary Vane Pump?

A rotary vane pump is a type of positive displacement pump. That’s a fancy way of saying it traps a fixed amount of fluid or gas and pushes it out. Picture a revolving door catching air and moving it through each spin. That’s close to how these pumps operate.

Inside, there’s a rotor with flat blades called vanes. These vanes slide in and out as the rotor spins. This creates chambers that grow and shrink. The growing chambers pull in fluid or gas. The shrinking ones push it out. This process delivers a steady flow. It’s why rotary vane pumps are great for tasks needing consistency, like fuel transfer or vacuum systems.

Rotary vane pumps are simple yet effective. They’ve been around for years, proving their worth in countless applications. Want to know more? Let’s look at how they work.

How Does a Rotary Vane Pump Work?

Understanding how a rotary vane pump functions is easy when broken into steps. Here’s how it happens:

The Rotor Starts Spinning

The rotor sits off-center in a round housing. When it spins, this offset makes the spaces between the rotor and housing change size. That’s the key to moving fluid or gas.

Vanes Move Outward

As the rotor turns, a force called centrifugal force pushes the vanes out. They slide from their slots in the rotor and touch the housing wall. This seals off sections inside the pump.

Chambers Take Shape

The vanes, rotor, and housing form little pockets or chambers. These chambers aren’t fixed. They get bigger on one side and smaller on the other as the rotor spins.

Suction Pulls Fluid In

When a chamber gets bigger, it creates a vacuum. This vacuum sucks fluid or gas in through the pump’s inlet. It’s like taking a deep breath to pull air into your lungs.

Fluid Gets Pushed Out

As the rotor keeps turning, the chamber shrinks. This squeezes the fluid or gas, forcing it out through the outlet. The cycle repeats with every spin.

This process happens smoothly. The offset rotor creates the pressure differences needed for suction and pushing. That’s why rotary vane pumps deliver a constant flow. Pretty neat, right? Next, let’s explore the different types.

Types of Rotary Vane Pumps

Not all rotary vane pumps are the same. Different designs suit different jobs. Here are the main types:

Sliding Vane Pumps

These have stiff vanes that slide in and out of the rotor. They’re rugged and reliable. You’ll find them moving liquids like fuel or oil. Their rigid design handles steady work well.

Flexible Vane Pumps

Instead of rigid vanes, these use bendy materials. The vanes flex as they spin. This makes them suitable for fluids with tiny bits or debris. They adjust to small changes in the liquid.

External Vane Pumps

Here, the vanes sit on the housing, not the rotor. This setup is less common but useful for high-pressure tasks. It offers precise control in specific situations.

Each type has its strengths. Picking the right one depends on what’s being pumped and how it’s used. Curious about what’s inside these pumps? Let’s check out their design.

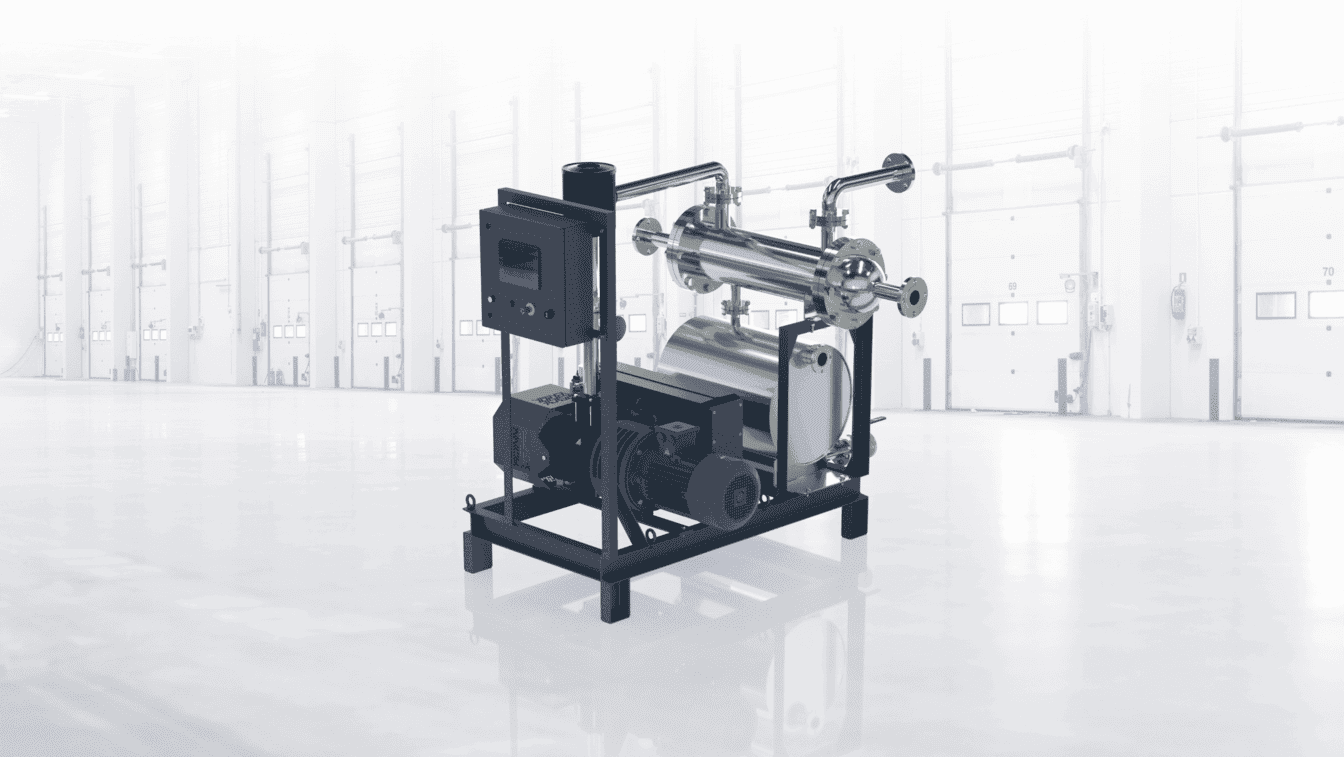

Design and Components of Rotary Vane Pumps

The design of a rotary vane pump is straightforward but smart. It relies on a few key parts working together. Here’s what’s inside:

The Rotor

This is the spinning heart of the pump. It holds the vanes and turns inside the housing. Usually, it’s made from strong stuff like stainless steel. That helps it last through tough jobs.

The Vanes

These flat blades slide in and out of the rotor. They’re often made from materials like carbon graphite. Why? Because it wears well, even with little lubrication. Vanes are the workhorses that trap and move fluid.

The Housing

The housing is the outer shell, typically round. It surrounds the rotor and vanes. Made from metals or alloys, it’s built to handle pressure. Its shape keeps everything in place.

Oil (Sometimes)

Some pumps use oil. It lubricates the parts so they move smoothly. It also seals tiny gaps between vanes and housing. This is common in vacuum pumps to keep air out.

Materials matter a lot. Stainless steel rotors resist rust in wet conditions. Carbon graphite vanes last longer in dry or rough jobs. The design balances strength and function. Want to know why these pumps are so popular? Let’s look at their advantages.

Advantages of Rotary Vane Pumps

Rotary vane pumps stand out for good reasons. Here’s why they’re loved in many fields:

Self-Priming Power

They can start pumping without being filled first. That saves time—no need to prime them manually before use.

Steady Flow

The design keeps the flow even. This is vital for tasks needing precision, like filling containers or running machines.

Handles Lots of Fluids

They work with thin liquids and gases alike. This versatility fits them into all sorts of industries.

Energy Savers

For low to medium-thickness fluids, they use less power. That cuts costs over time.

Small Size

They’re compact. This makes them easy to fit into tight spots, like car engines or small workshops.

These perks make rotary vane pumps a top pick. But they’re not perfect. Let’s see their downsides next.

Limitations of Rotary Vane Pumps

No pump is flawless. Rotary vane pumps have limits to watch for:

Trouble with Thick Fluids

High-viscosity liquids, like heavy oils, can jam the vanes. They wear out faster or stop moving.

Weak Against Dirt

Abrasive bits in the fluid—like sand—can scratch vanes and housing. This leads to damage and repairs.

Needs Care

They’re reliable but not maintenance-free. Oil changes and valve checks are a must to keep them going.

Knowing these limits helps pick the right pump. For thick or gritty fluids, other options might work better. Now, let’s see where these pumps shine.

Applications of Rotary Vane Pumps

Rotary vane pumps pop up everywhere. Their flexibility makes them handy in many places. Here are some examples:

Cars and Trucks

In vehicles, they power the steering systems. They make turning the wheel smooth. They also help with air conditioning and fuel lines.

Food and Drinks

Ever enjoy an espresso? These pumps push water through coffee grounds at the correct pressure. They’re also in soda machines for steady fizz.

Factory Vacuums

In industries, they create vacuums. This is useful for packaging, lifting materials, or drying products.

Chemical Work

They move chemicals safely. Their design handles different liquids without leaks or fuss.

These uses show how adaptable rotary vane pumps are. They tackle both liquids and gases with ease. Want them to last? Maintenance is key. Let’s talk about that.

Maintenance Tips for Rotary Vane Pumps

Keeping a rotary vane pump in top shape isn’t hard. A few simple steps go a long way. Here’s how:

Change the Oil

If the pump uses oil, swap it out regularly. Check the maker’s guide for timing. Fresh oil keeps parts moving smoothly.

Inspect the Vanes

Look at the vanes now and then. Are they worn or chipped? Replace them to avoid breakdowns.

Clean Everything

Keep the pump and area free of dust or bits. Debris can sneak in and cause trouble.

Don’t Run Dry

Pumping without fluid damages parts fast. Always make sure there’s something to pump.

These habits extend a pump’s life. They cut downtime and repair costs, too. Wondering how these pumps compare to others? Let’s find out.

Comparison with Other Pumps

Rotary vane pumps aren’t the only option. How do they stack up? Here’s a quick look:

Against Gear Pumps

Gear pumps move fluid with spinning gears. They’re loud and less smooth with thin fluids. Rotary vane pumps run quieter and handle low-viscosity stuff better.

Versus Centrifugal Pumps

Centrifugal pumps use a spinning wheel for high flow. They’re great for enormous volumes but falter with changing pressure. Rotary vane pumps keep the flow steady at any pressure.

Each pump has its place. For consistent flow or tight spaces, rotary vane pumps often win. Ready for the wrap-up? Here’s the conclusion.

Conclusion

Rotary vane pumps prove that engineering can be simple yet powerful. They move fluids and gases reliably across industries. From car steering to coffee machines, their impact is enormous. The design blends ease with efficiency, making it a favorite for many jobs. At Mechvac Technologies, high-quality rotary vane pumps are crafted to last. They’re built for top performance, no matter the task. Need a pump for cars, food, or vacuums? Check out what’s on offer and see the difference quality makes.