What is a Mechanical Booster Vacuum Pump?

Imagine setting up a high-efficiency vacuum system for a chemical or pharmaceutical facility.

You need a pump that’s not only reliable but also powerful enough to maintain the vacuum levels required for your processes. This is where the mechanical booster vacuum pump comes in!

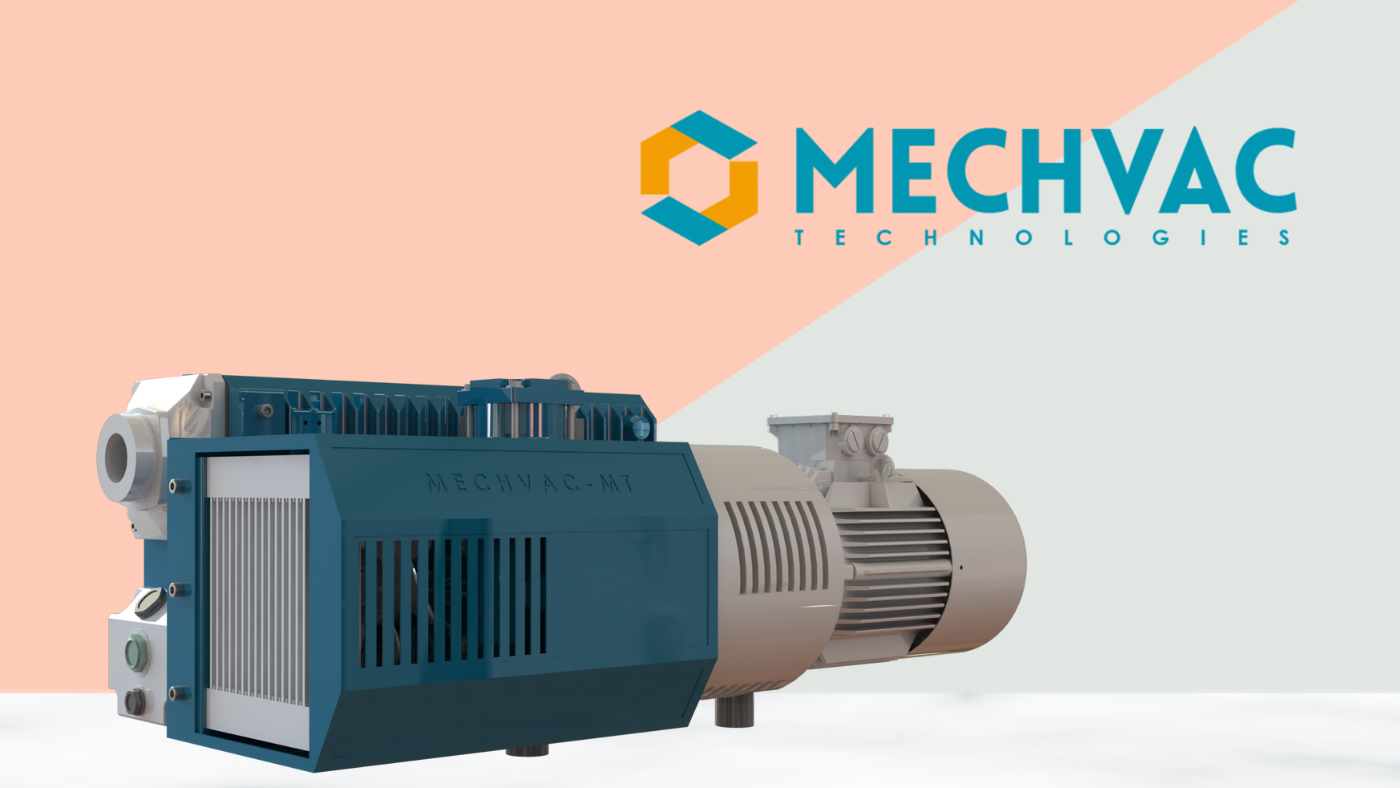

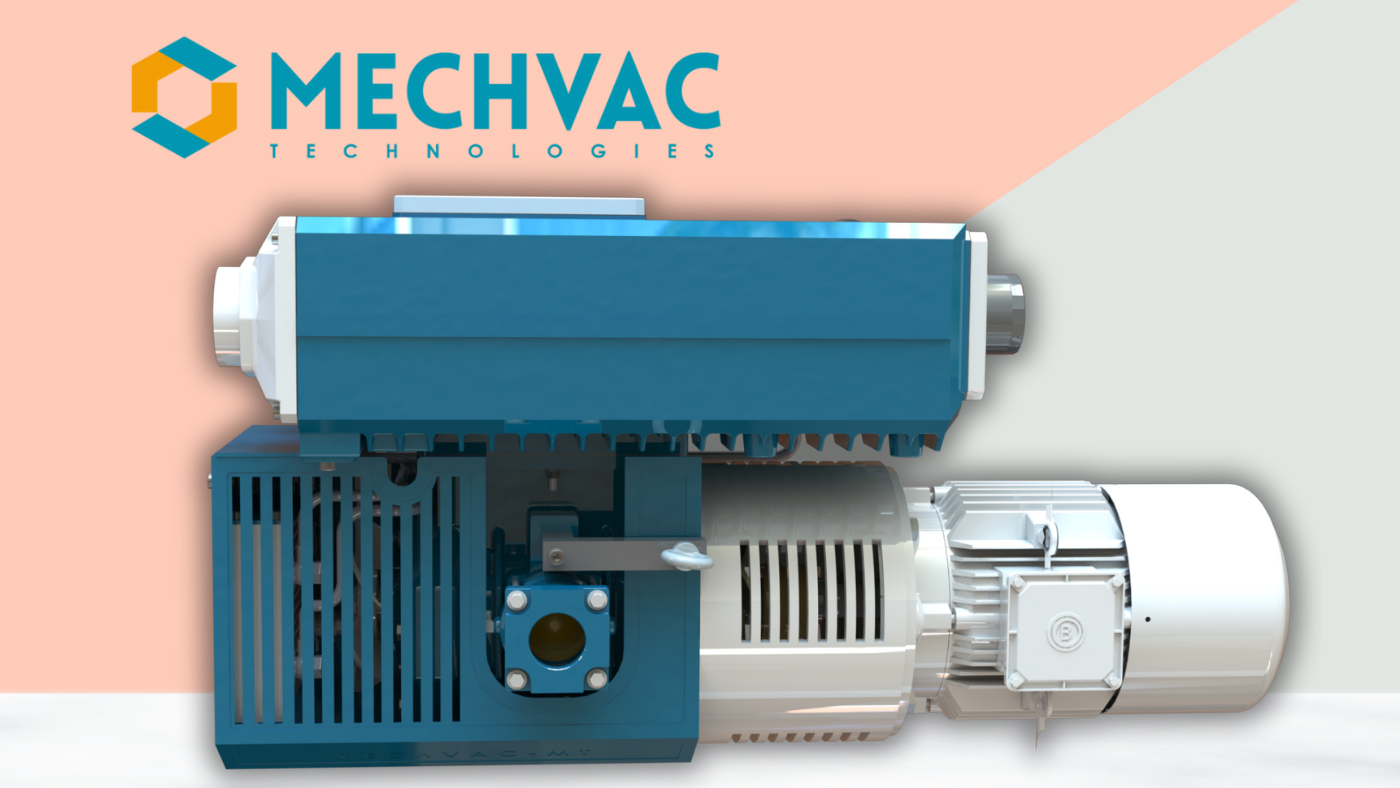

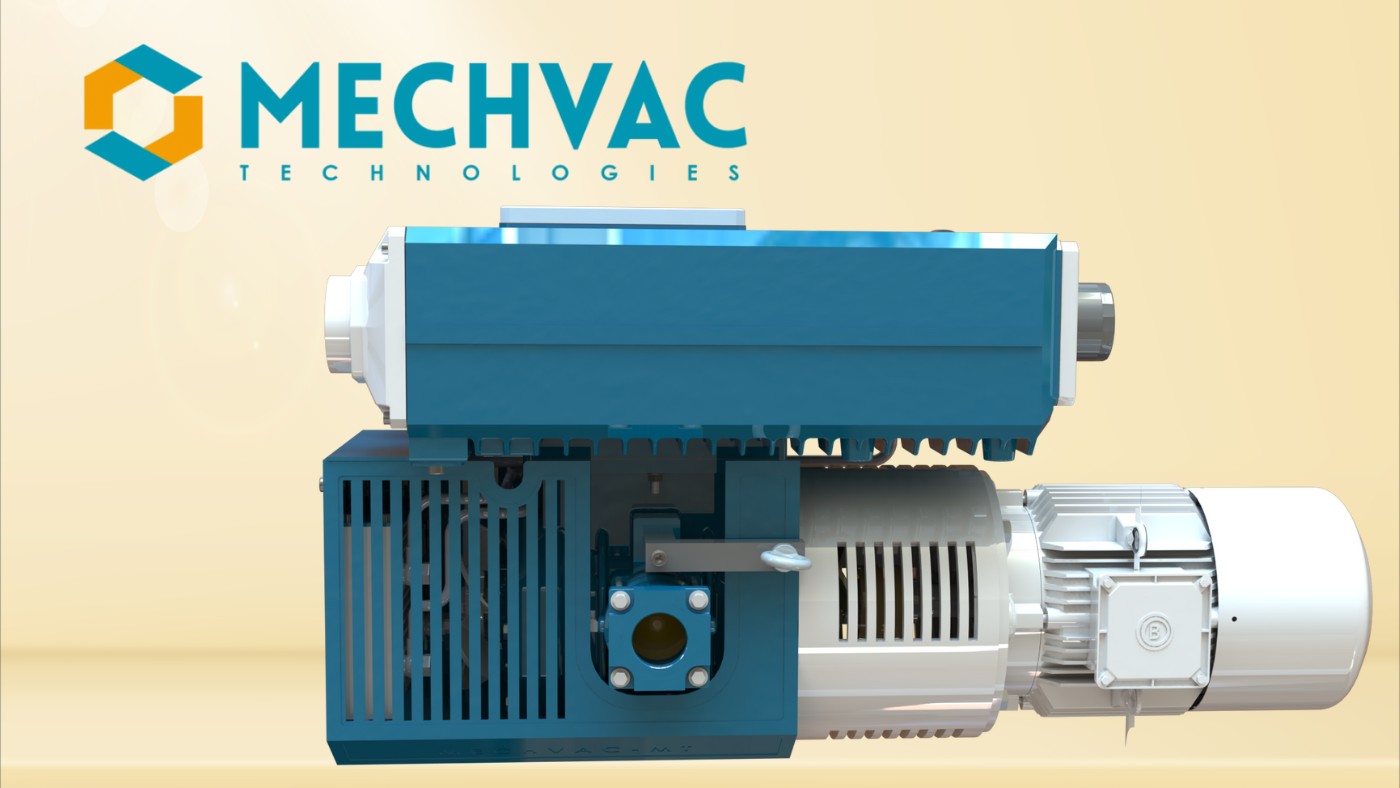

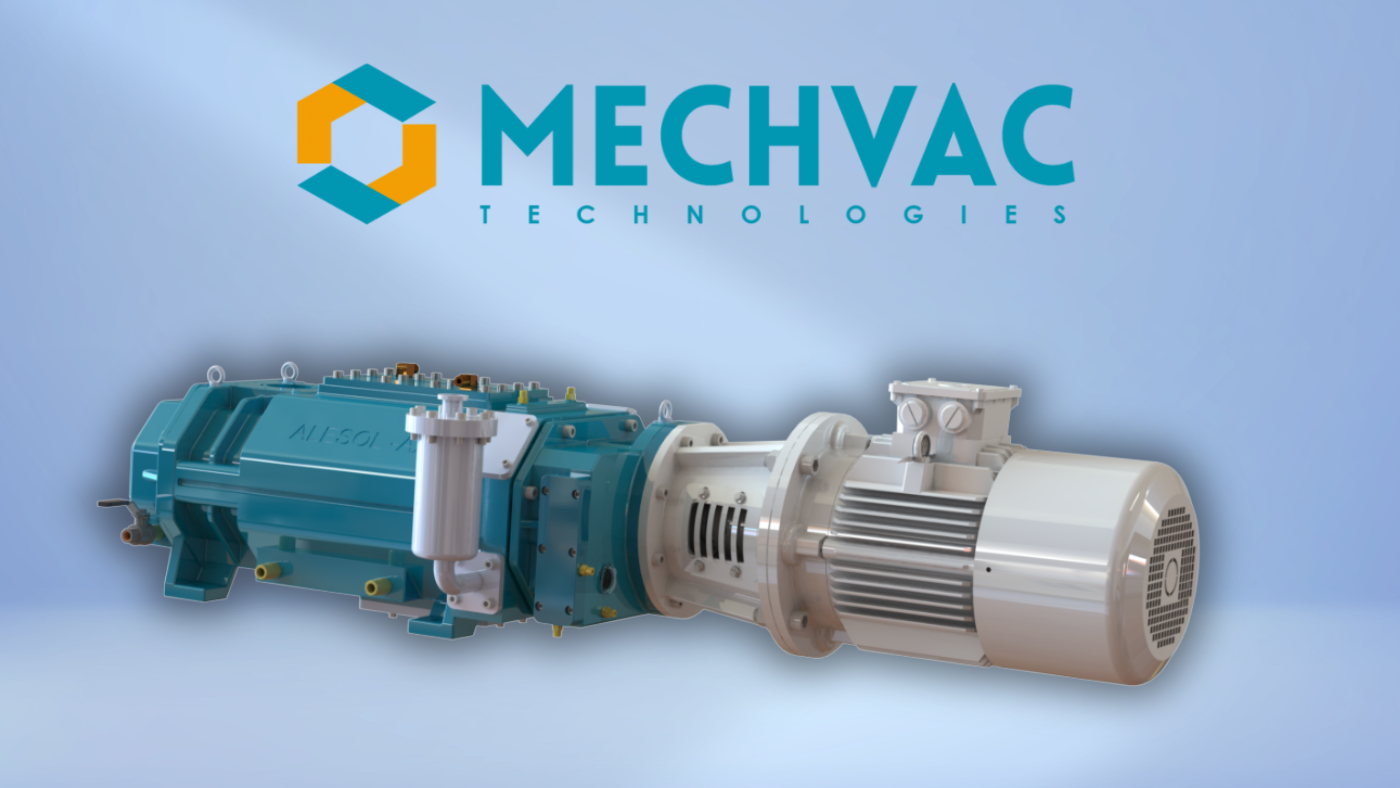

A mechanical booster vacuum pump, often called a Roots pump, enhances the vacuum system’s overall performance.

It works with a primary pump (such as a rotary vane or piston pump) to achieve deeper vacuum levels and improve system efficiency.

This type of pump is popular across industries for its unique benefits and reliable operation, offering process engineers a valuable tool for vacuum optimization.

How Mechanical Booster Vacuum Pumps Work

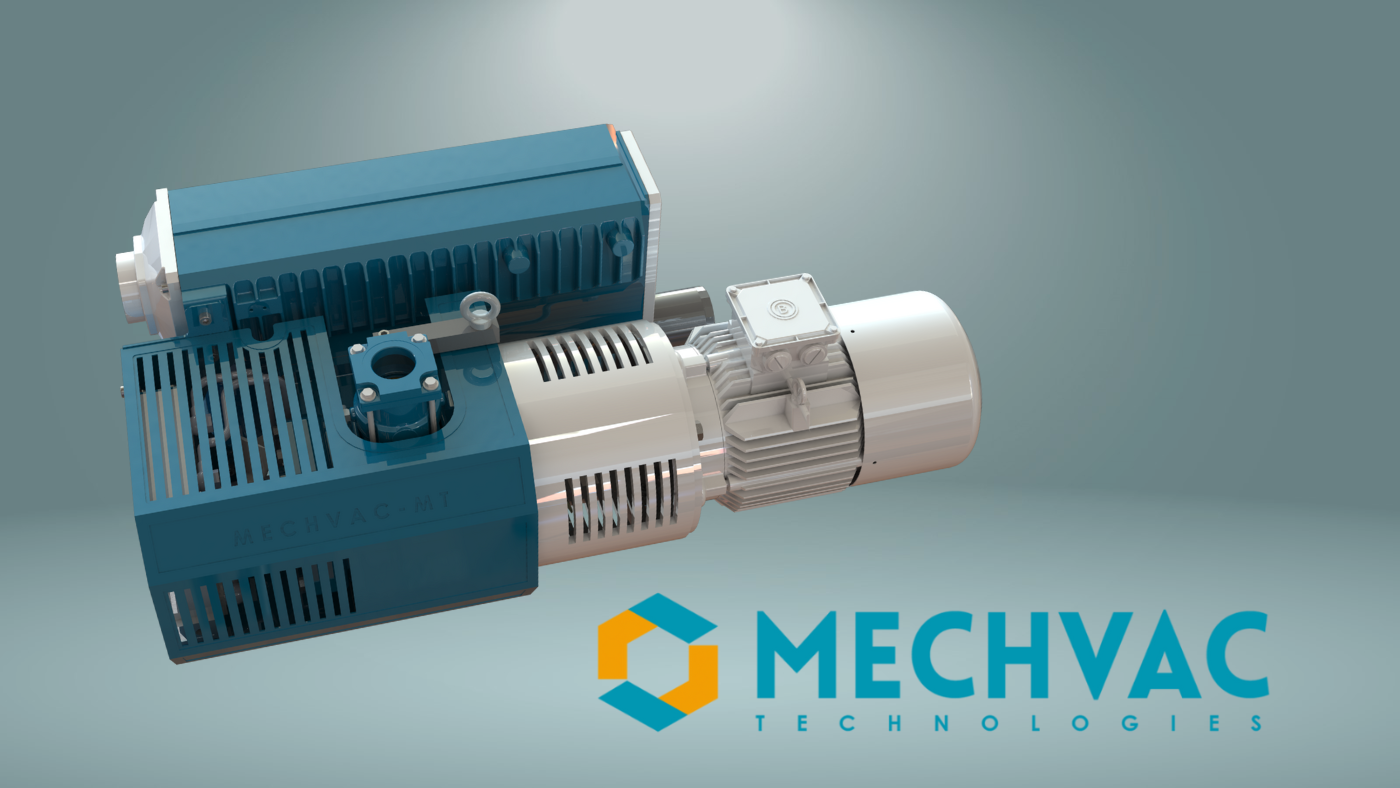

Mechanical booster vacuum pumps operate on a positive displacement principle. Inside the pump, two synchronized rotors spin, creating volumes of space that draw gas in, compress it, and push it out through the exhaust.

These pumps rely on a primary pump to first reduce the gas pressure before it reaches the booster pump, making the overall system more efficient.

Together, the primary and booster pumps allow the system to achieve higher pumping speeds and deeper vacuum levels than a primary pump alone.

To ensure these pumps work within optimal pressure ranges, they are generally equipped with a bypass valve or variable frequency drive. This keeps them protected and operating efficiently, avoiding the risk of overpressure damage.

Key Benefits of Mechanical Booster Vacuum Pumps

Adding a mechanical booster pump to your vacuum system brings several major advantages:

- Higher Pumping Speed: By boosting the performance of the primary pump, a mechanical booster pump increases the system’s overall speed, reducing the time needed to achieve the target vacuum.

- Deeper Vacuum Levels: Mechanical booster pumps can reach lower vacuum pressures, which is essential in applications that require a high level of vacuum for optimal results.

- Energy Efficiency: Designed to operate with less energy than other types of vacuum pumps, mechanical booster pumps can help reduce operating costs and minimize environmental impact.

Common Applications of Mechanical Booster Vacuum Pumps

Mechanical booster vacuum pumps are widely used across many industries:

- Chemical Processing: These pumps enhance vacuum levels in processes like distillation, evaporation, and drying, ensuring high-quality outputs.

- Pharmaceutical Manufacturing: In pharmaceuticals, mechanical booster pumps support processes like freeze-drying, sterilization, and degassing, which help produce safe, effective medications.

- Vacuum Furnaces: Mechanical booster pumps help achieve required vacuum levels in vacuum furnaces used for heat treatments such as brazing, sintering, and annealing, resulting in superior material quality.

Conclusion: Why Choose Mechanical Booster Vacuum Pumps?

Mechanical booster vacuum pumps are essential for process engineers in various industries, delivering faster pumping speeds, lower vacuum pressures, and better energy efficiency.

They are ideal for optimizing vacuum systems in chemical, pharmaceutical, and furnace applications, among others.

How Mechvac Technologies Can Help

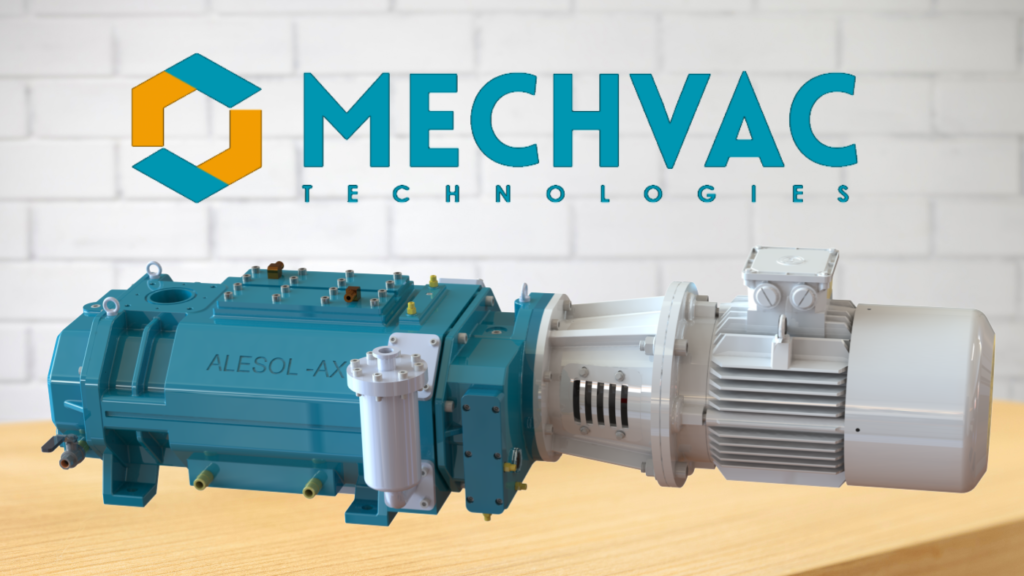

Looking to integrate a mechanical booster vacuum pump into your system? The team at Mechvac Technologies is here to help you find the best pump solution for your unique process requirements.

We’ll work with you to design a vacuum system that maximizes performance and efficiency. Contact us today to learn more about how our mechanical booster pumps can elevate your operations!