Vacuum pumps are powerful tools used in many industries to create and maintain a vacuum or low-pressure environment, which is essential for various processes.

They work by removing gas molecules from a closed space, making them vital for industries like manufacturing, research, and healthcare.

Different types of vacuum pumps operate in unique ways, with each type offering specific advantages for particular applications. This guide breaks down the most common types, how they work, and where they’re used, so you can choose the best one for your needs.

Types of Vacuum Pumps and How They Work

Each vacuum pump type is designed with specific features, making it suitable for certain tasks.

Here are some of the main types you’ll find on the market:

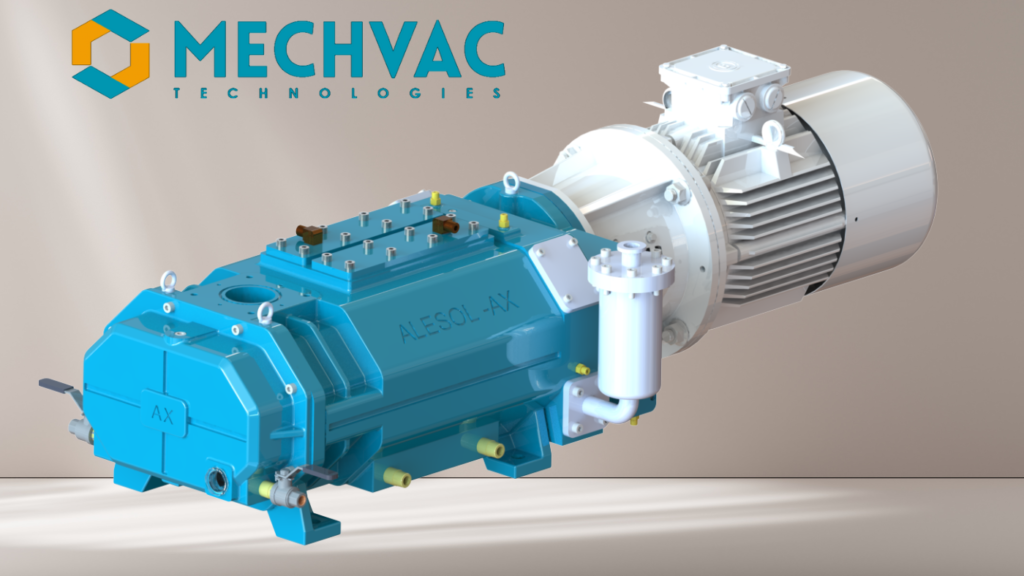

1. Dry Screw Vacuum Pumps

These pumps don’t require oil or water for sealing, using interlocking screws to compress gas and create a vacuum. They’re reliable, low-maintenance, and ideal for clean environments.

2. Mechanical Booster Vacuum Pumps

Used alongside primary vacuum pumps, mechanical boosters increase performance by using mechanical compression to reach higher vacuum levels. They’re effective for applications needing a stronger vacuum than primary pumps alone can provide.

3. Rotary Vane Vacuum Pumps

These pumps use rotating vanes to draw gas into a chamber and expel it, creating a moderate vacuum. They are known for being compact, cost-effective, and versatile across many industries.

4. Hook and Claw Dry Vacuum Pumps

With a claw mechanism that compresses gas, these oil-free pumps suit clean environments, providing high-speed pumping with minimal maintenance needs.

5. Liquid Ring Vacuum Pumps

Using a rotating liquid (often water) to compress gas, these pumps are tough and can handle particles in the gas stream. They’re popular in industries needing a higher vacuum level.

6. Rotary Piston Vacuum Pumps

Rotating pistons compress gas, creating a reliable high-vacuum pump that operates quietly. These pumps are valued for their durability and consistent performance.

7. Twin Lobe and Trilobe Blowers

Also known as “roots blowers,” these pumps use lobes to move gas and are suitable for applications with high flow rates but low vacuum needs, like wastewater management.

8. Customized Vacuum Skids

Designed for specific applications, customized vacuum skids integrate various components for optimal performance and efficiency in specialized industries.

9. Positive Displacement Vacuum Pumps

These pumps trap gas in a confined space, then reduce the space to create a vacuum. They include options like rotary vane and diaphragm pumps, suitable for handling condensable vapors.

10. Diaphragm Vacuum Pumps

Using a flexible diaphragm to expand and contract within a chamber, these pumps generate a clean, oil-free vacuum, ideal for sensitive applications needing contamination-free results.

11. Momentum Transfer Vacuum Pumps

Using high-speed jets or vapor to create a vacuum, these pumps are efficient for high-speed gas handling in applications like ejectors and steam systems.

12. Turbomolecular Vacuum Pumps

These pumps have high-speed blades that transfer momentum to gas molecules, creating an ultra-high vacuum ideal for research labs and semiconductor manufacturing.

13. Diffusion Vacuum Pumps

Operating by creating a vapor jet that captures gas molecules, diffusion pumps are used in high-vacuum applications and typically work with other pumps.

14. Entrapment Vacuum Pumps

Entrapment pumps capture gas molecules on a surface or in a porous material. Examples include cryogenic pumps and getters, often used in ultra-high vacuum situations.

15. Cryogenic Vacuum Pumps

By using cryogenic temperatures to condense gases, these pumps can achieve an extremely high vacuum, suitable for research and high-precision manufacturing.

16. Ion Getter Vacuum Pumps

Using electric fields and ionization to capture gas, these pumps provide ultra-high vacuum levels, essential in advanced scientific research.

Where Vacuum Pumps Are Used

Vacuum pumps play a crucial role across multiple sectors, from industrial manufacturing to scientific labs and healthcare. Here’s how they support different fields:

- Industrial Applications: Common in distillation, drying, and packaging, vacuum pumps help control atmospheres and enhance product quality across food, pharmaceutical, automotive, and electronics industries.

- Research and Laboratories: Used in labs with equipment like electron microscopes, vacuum pumps enable precise measurements and sample preparation, supporting research in physics, chemistry, and biology.

- Medical Applications: Vacuum pumps are essential in medical devices for surgeries, wound drainage, and respiratory support, aiding patient safety and surgical accuracy.

Choosing the Right Vacuum Pump

Selecting the right pump depends on several factors. Understanding these can ensure you choose a pump that meets your specific needs:

- Performance Requirements: Consider the level of vacuum required, pumping speed, and gas handling capabilities. Higher vacuums are often needed for scientific or manufacturing applications.

- Operating Conditions: Factors like temperature, humidity, and gas types affect a pump’s performance. Choose one designed for your specific working conditions.

- Maintenance Needs: Different pumps have varied maintenance demands. Consider oil changes, cleaning needs, and parts availability to ensure longevity and low downtime.

Pros and Cons of Different Types of Vacuum Pumps

Positive Displacement Vacuum Pumps

- Pros: Effective at high vacuums, oil-free, good for handling condensable vapors

- Cons: Limited speed, potential backflow, periodic maintenance needed

Momentum Transfer Vacuum Pumps

- Pros: Fast pumping speed, minimal moving parts, large gas volume handling

- Cons: Limited high-vacuum level, higher energy use, sensitive to conditions

Entrapment Vacuum Pumps

- Pros: High vacuum level, no moving parts, efficient gas removal

- Cons: Lower pumping speeds, requires cooling, higher initial investment

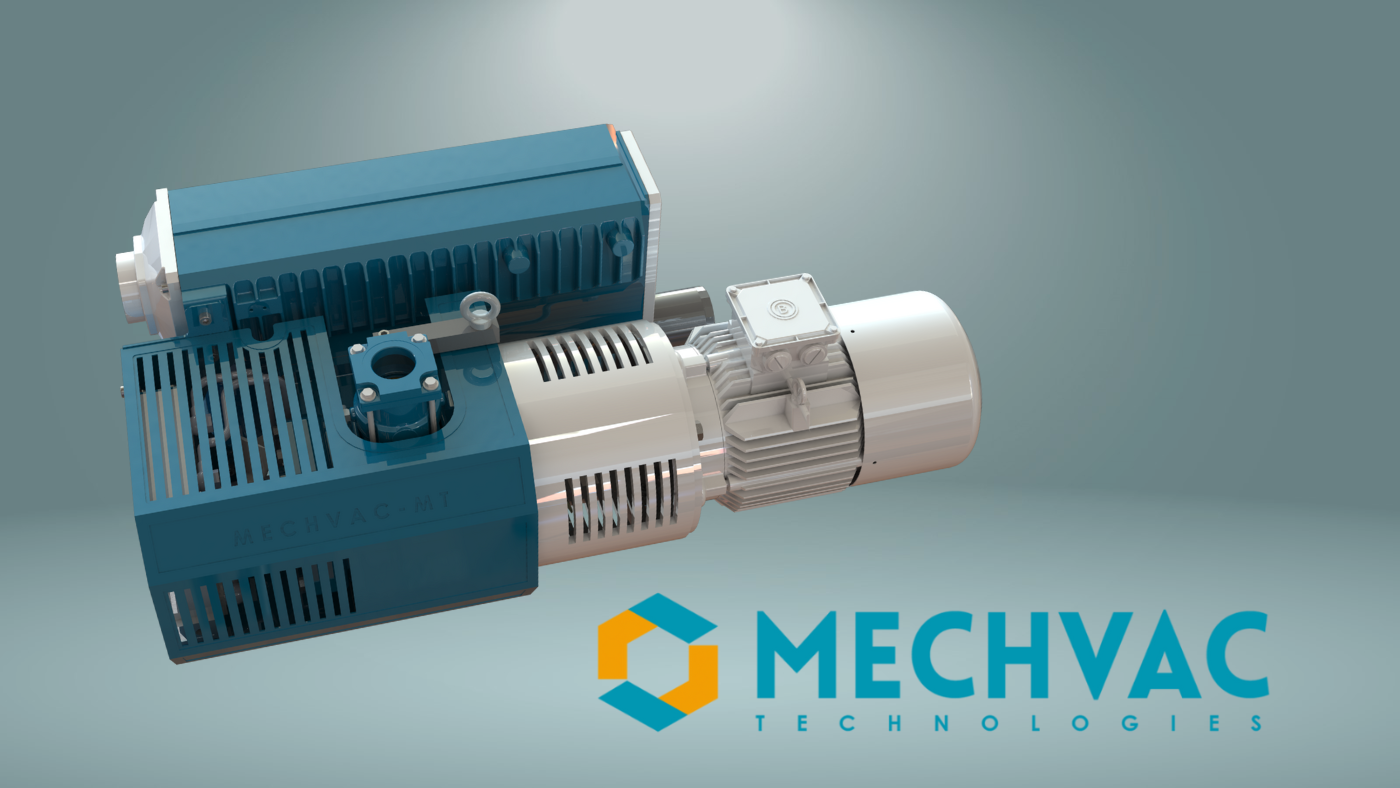

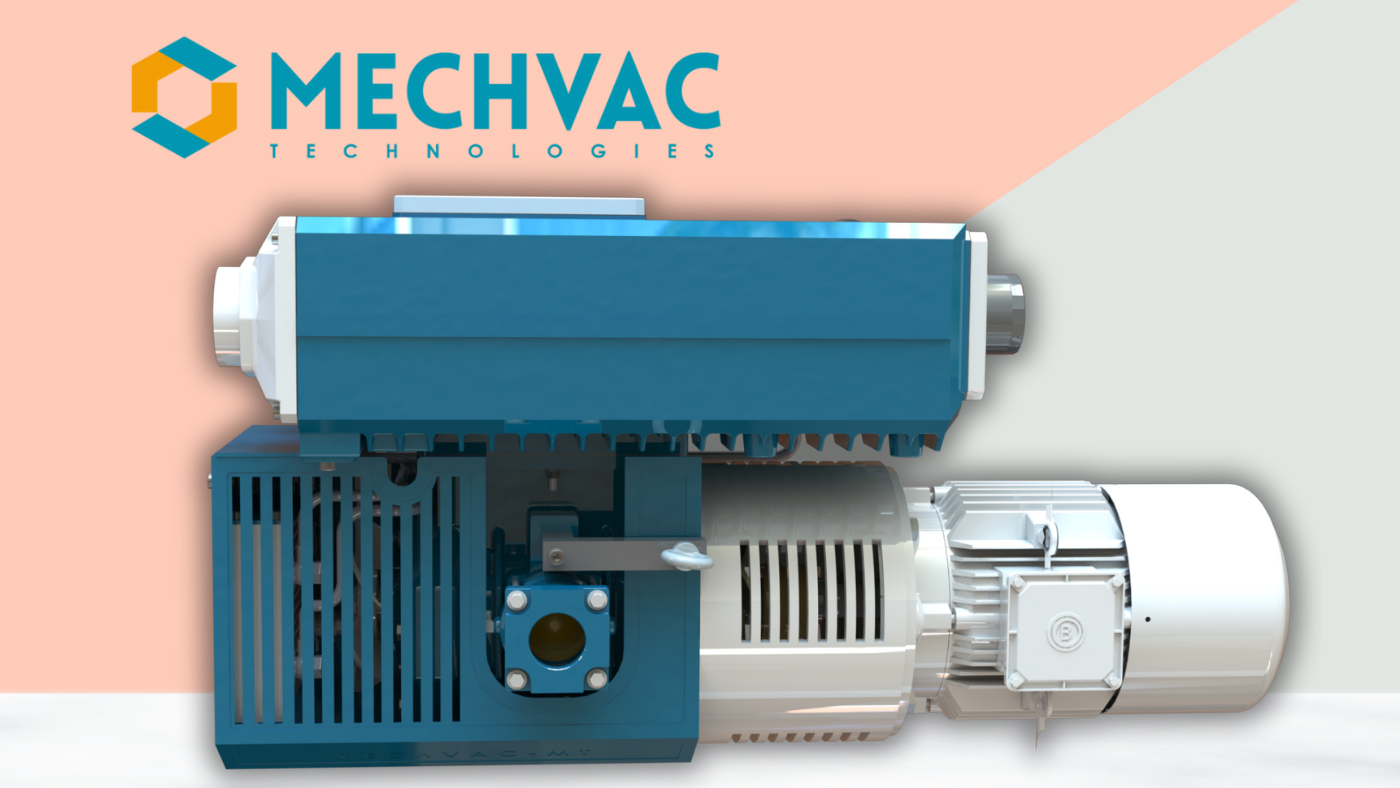

Conclusion: How Mechvac Technology Can Help

Mechvac Technologies offers a wide range of vacuum pumps to suit diverse industry needs worldwide.

Whether you require a high-speed, oil-free pump for a cleanroom, a robust pump for industrial processes, or a specialized vacuum system for scientific applications, Mechvac Technology provides reliable, high-quality solutions tailored to your specifications.

Reach out to us to find the perfect vacuum pump solution for your business, backed by expert support and guidance for optimized performance.