With a rising demand for eco-friendly and sustainable energy, renewable sources like solar power are more important than ever. Among these options, solar energy is highly researched and increasingly used.

In India, the National Solar Mission (NSM) program, under the Ministry of New and Renewable Energy (MNRE), has been active in expanding the use of solar power in areas like electricity production, heating, and cooling for industrial and domestic applications.

The simplest way to harness solar power is through the photovoltaic (PV) process. This method generates electricity when sunlight interacts with the silicon in photovoltaic panels.

Dry vacuum pumps are particularly useful in the production of photovoltaic cells and modules. They are frequently used in various solar cell manufacturing steps worldwide, including:

- Wafer Coating

- Single and Polycrystalline Silicon Production

- Compressing Photovoltaic Cells

Why Vacuum Pumps are Vital in Solar PV Manufacturing

The solar PV industry has grown due to advancements in the semiconductor sector. Solar PV technology now includes traditional crystalline-Si-based cells and thin-film technologies, such as amorphous/microcrystalline silicon (a/µ-Si), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS).

Each technology involves various manufacturing steps, where vacuum pumps play an essential role.

The Role of Vacuum Pumps in Different Solar PV Manufacturing Steps

Vacuum Pumps for Silicon Production

For both monocrystalline and polycrystalline silicon production, vacuum pumps are essential. During the silicon production process, a vacuum pump is exposed to large amounts of reactive silicon oxide (SiO) dust.

Solar cells made from monocrystalline silicon are more efficient than those made from polycrystalline silicon. To achieve high efficiency, substances called dopants are added while the silicon crystal grows.

This process needs a reliable vacuum pump that can work effectively even in environments with high levels of by-products.

A screw vacuum pump can be paired with a Roots vacuum pump to increase the pumping speed in the required pressure range.

These pumps can operate at low pressures (0.01 to 0.3 mbar) and provide different pumping speeds from 70 up to 630 cubic meters per hour.

When combined with a Roots pump, the pumping speed can exceed 4,000 cubic meters per hour.

Vacuum Pumps for Solar Cell Fabrication

After creating the silicon wafers, they are used to produce solar cells. Several steps are involved, such as doping and diffusion, etching, plasma-enhanced chemical vapor deposition (PECVD), and physical vapor deposition (PVD).

These processes produce corrosive particles and large amounts of dust. A dry screw vacuum pump is ideal for this stage due to its ability to resist corrosion and handle high dust levels effectively.

Vacuum Pumps for Solar Module Assembly

In this step, the solar cells are arranged in a matrix and soldered together with metal connectors to form a panel. The cells are then encapsulated to protect them from harsh weather like rain, snow, or hail.

Encapsulation is done by processing ethylene vinyl acetate (EVA) at high temperatures in a vacuum chamber. The vacuum pump must handle EVA material efficiently. Choosing an energy-efficient pump that can handle EVA is crucial.

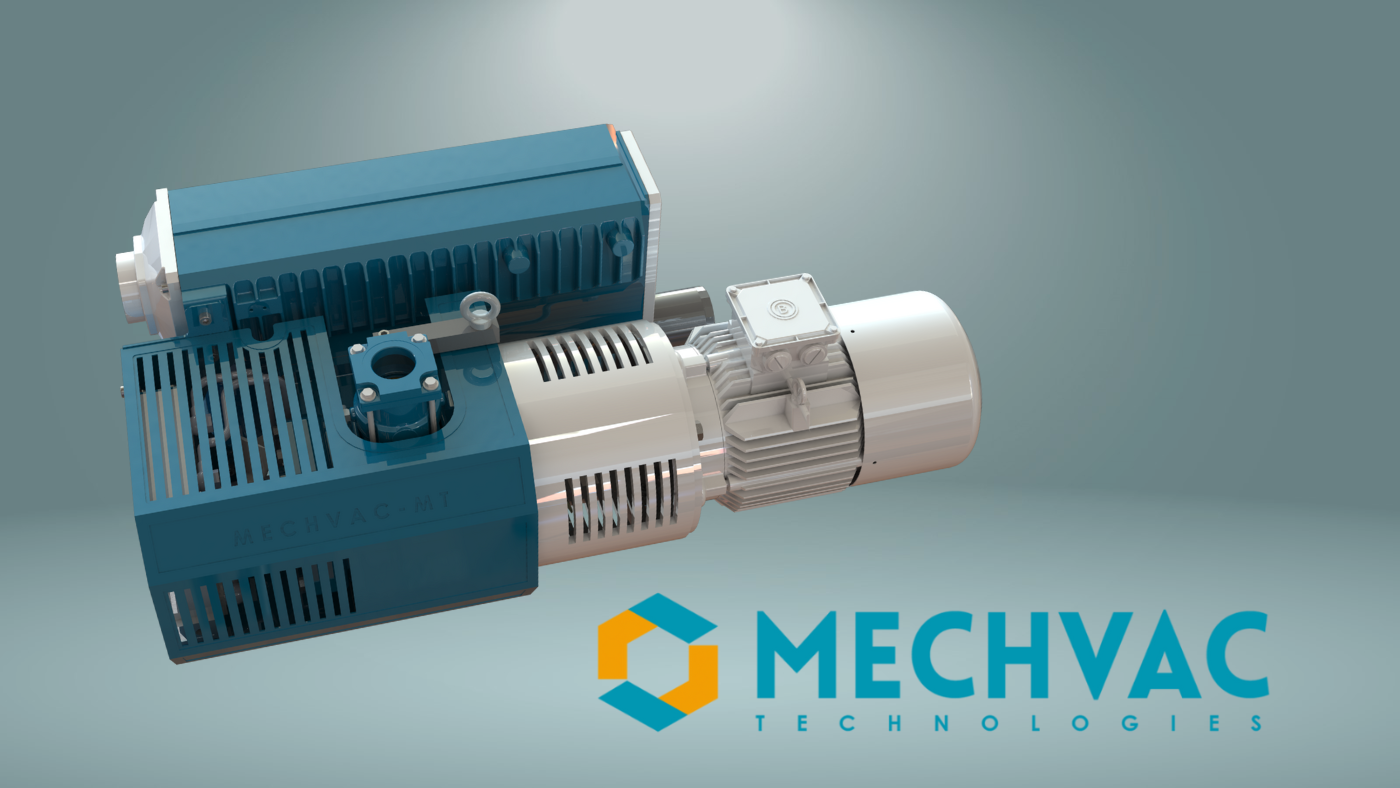

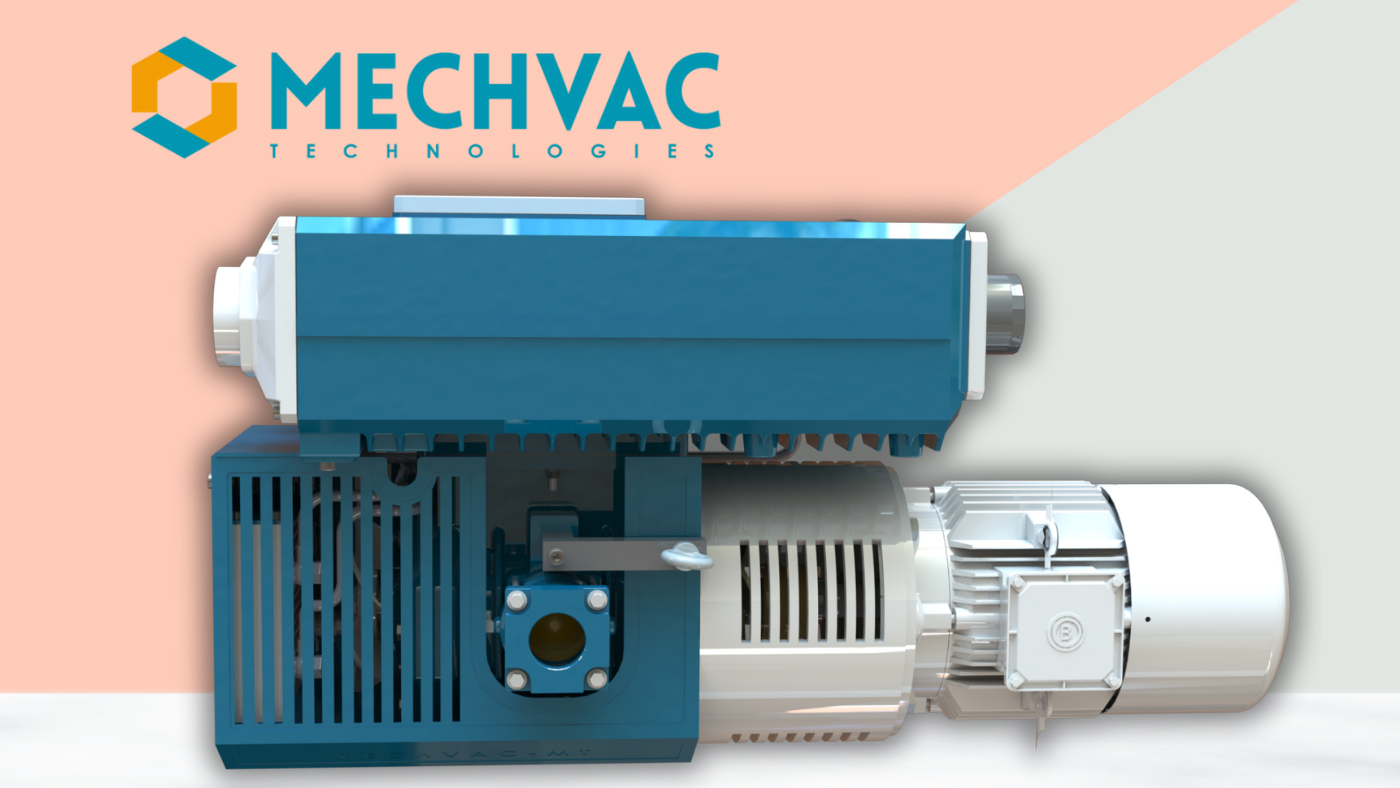

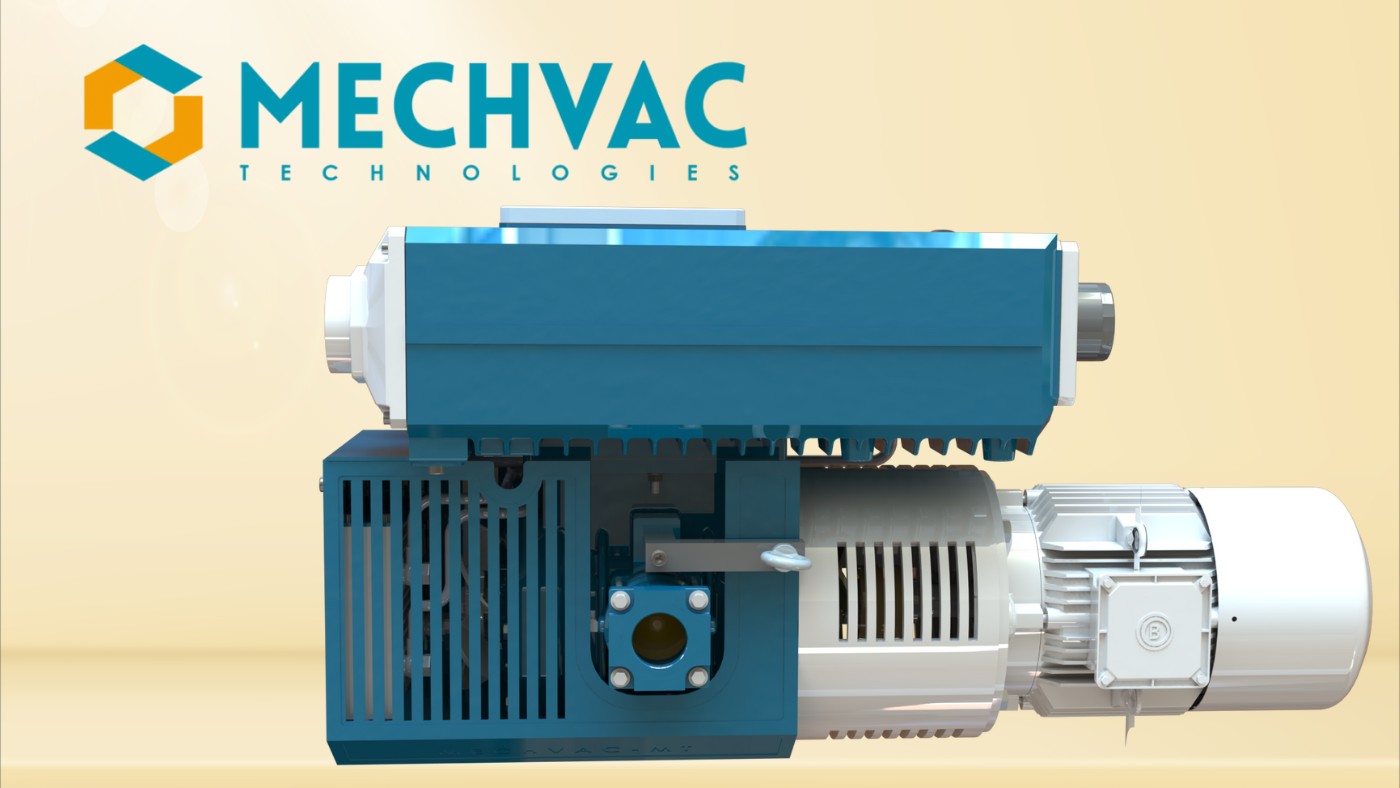

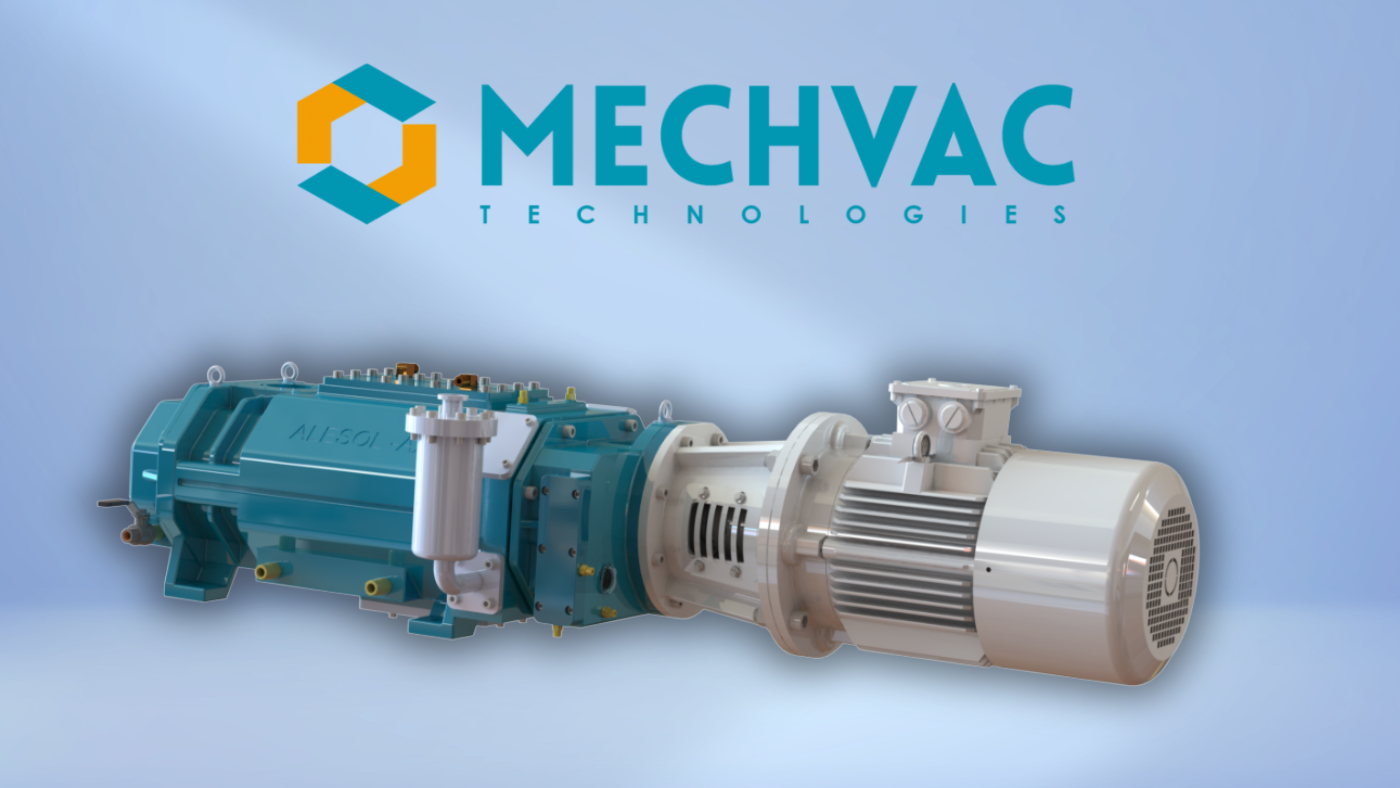

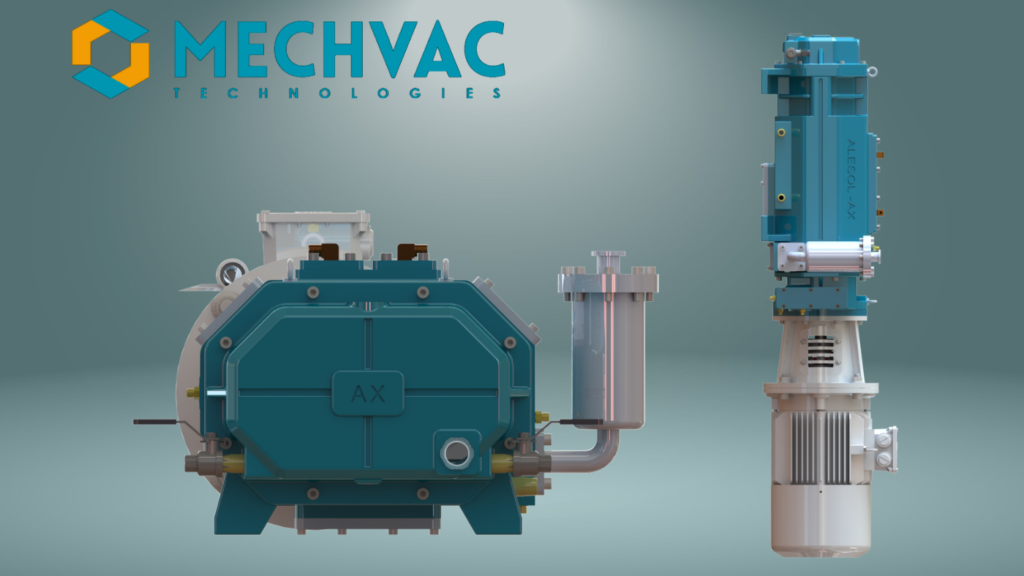

Mechvactech’s Dry Screw Vacuum Pump

Mechvactech Vacuum, a brand by Mechvac Technologies Private Limited, offers the Superscrew ESPH series of dry screw vacuum pumps.

These pumps are versatile and suitable for a wide range of applications, such as chemical, pharmaceutical, petrochemical, food processing, CD-DVD manufacturing, thin-film production, and especially the solar PV industry.

Mechvactech Vacuum Pumping Systems stand out for their reliability, innovative design, and quality. Their advanced screw design not only saves energy but also reduces heat during the compression process.

These pumps operate without oil or water, ensuring that process vapors pass through without contamination, making them environmentally friendly. Additionally, a vent condenser captures these vapors, creating an efficient vapor recovery system.

Market Demand for Dry Vacuum Pumps

In 2021, dry vacuum pumps represented about 3.2% of the global industrial pump market. The market grew at an average annual rate of 5.8% from 2013 to 2021.

With a projected annual growth rate of 6.1%, the global dry vacuum pump market is expected to grow from $2.25 billion in 2022 to $3.22 billion by 2028.

This easy-to-understand guide aims to provide insights into the role and importance of dry screw vacuum pumps in solar power production.

Whether for professionals in the solar industry or anyone interested in solar technology, understanding these processes and equipment will help shed light on how solar PV cells are made and how dry vacuum pumps play a part in a more sustainable future.