Imagine a process that separates liquids to make something pure and safe, like the brake fluid in your car. That’s what distillation does. It’s a method used in many industries to create high-quality vacuum products by heating liquids and collecting their vapors.

This is super important for things like chemicals, medicines, food, and even eco-friendly fuels. In the car industry, distillation helps make brake fluid that keeps your brakes working smoothly.

Why Dry Vacuum Pumps Matter

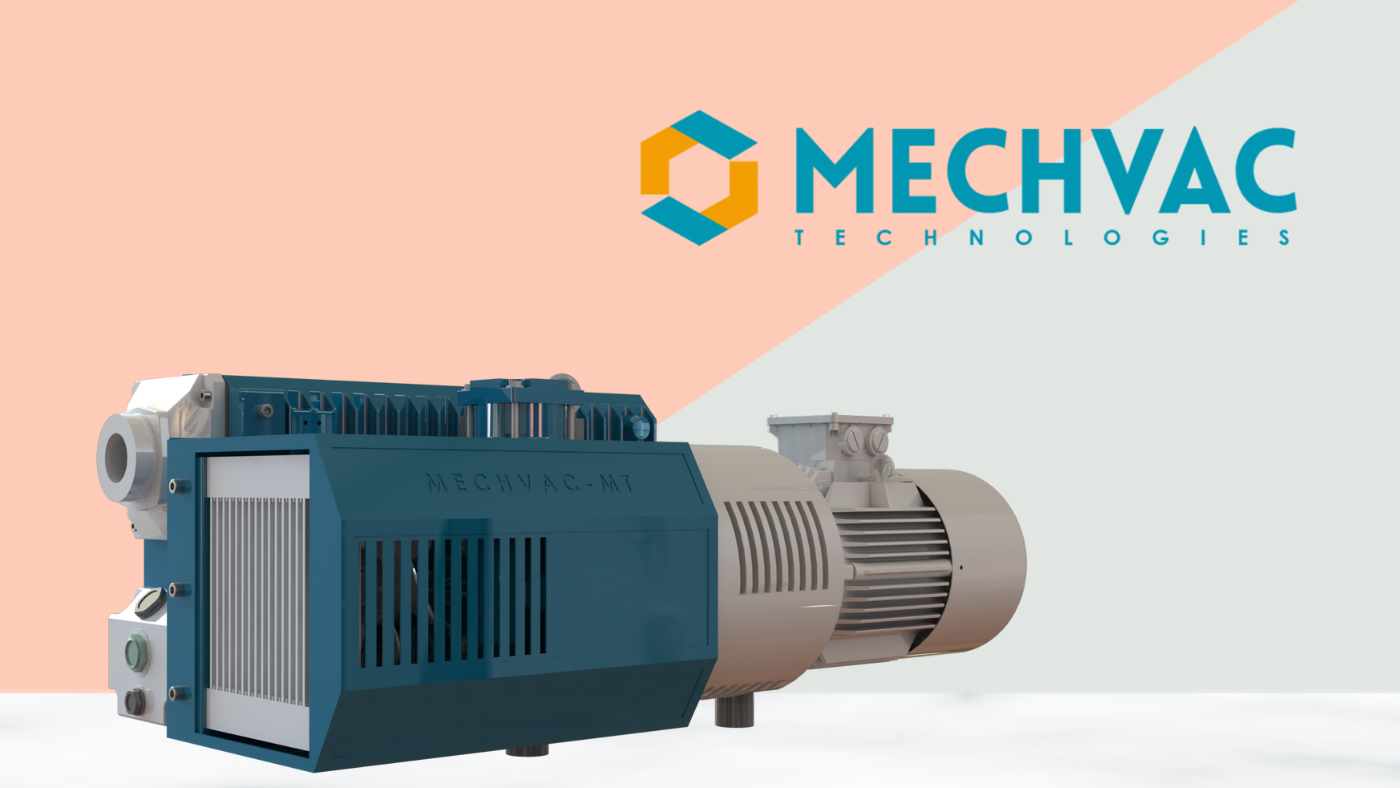

Lately, dry vacuum pumps have become a big deal in these industries. Unlike older pumps that use oil or water, these are cleaner and kinder to the environment.

They create a strong vacuum, which is key for distillation, and they don’t need much upkeep. That’s why companies love them; they’re tough and reliable.

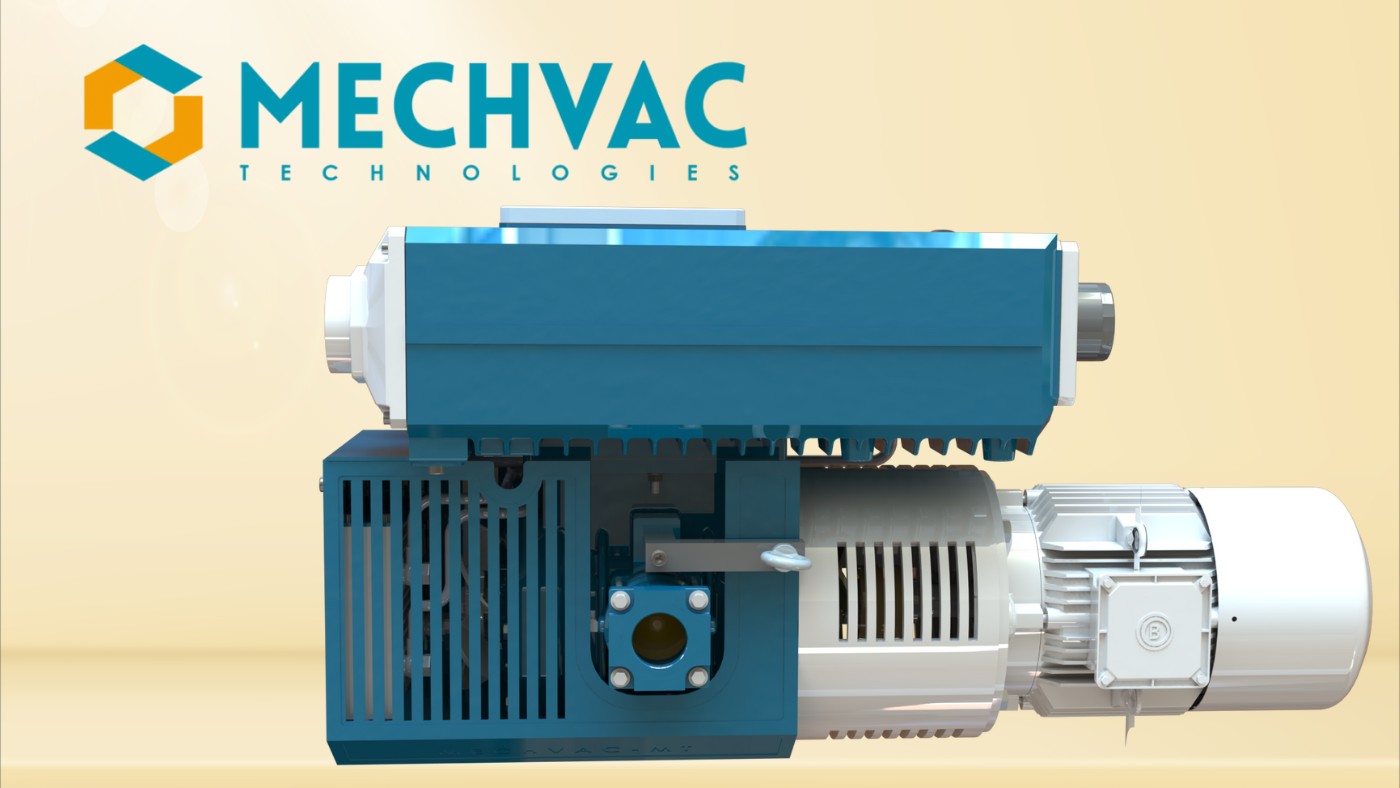

Two Types of Dry Vacuum Pumps

There are two main kinds of dry vacuum pumps: Screw Coated Dry Vacuum Pumps and Dry Claw Vacuum Pumps. Both help with distillation, but they’re not the same. Let’s see how they differ.

Screw Coated vs. Dry Claw Pumps

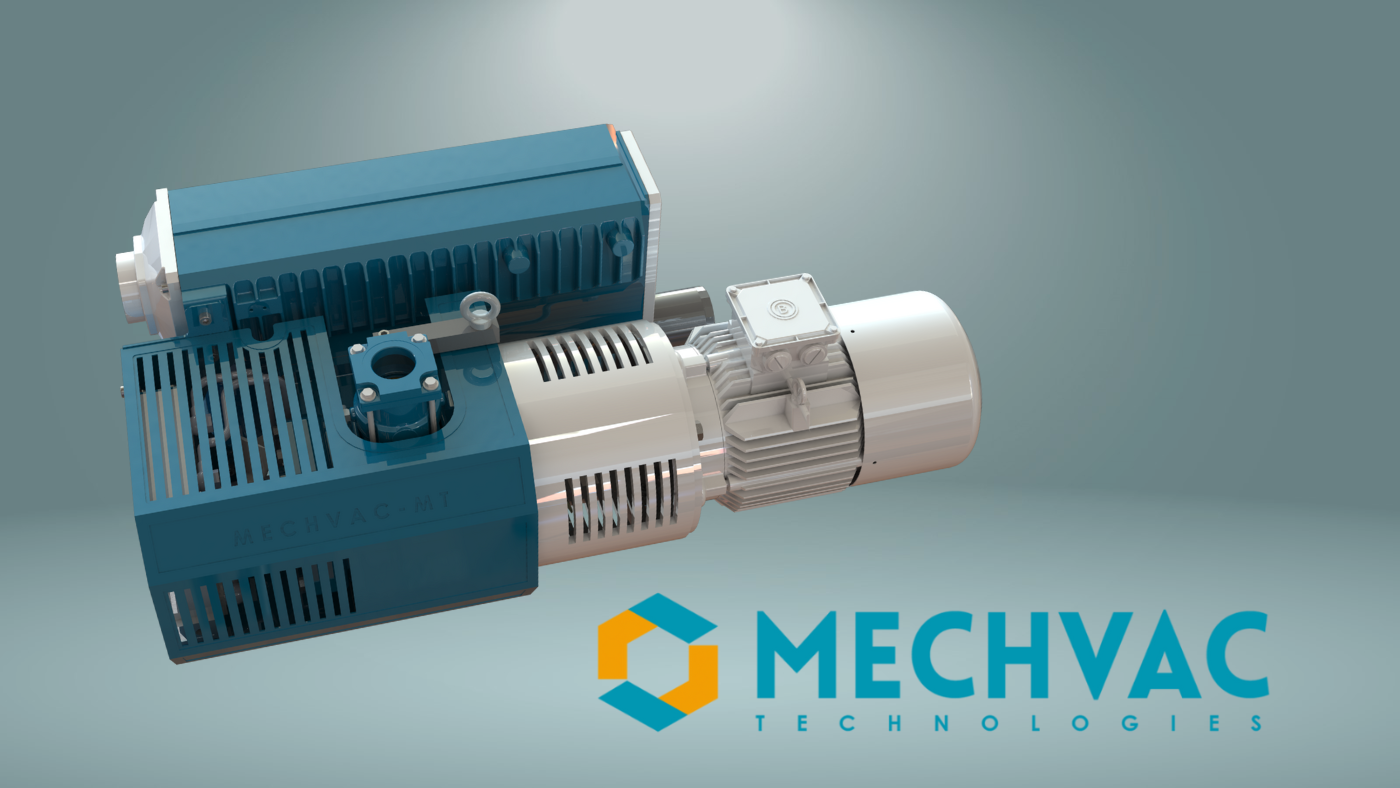

Screw Coated pumps have a special layer that can wear out, especially when it gets hot. This can cause rust and breakdowns. Sometimes, vapors inside turn sticky and clog things up, making repairs a headache. Dry Claw pumps, though, don’t have that layer.

They’re built to handle heat and tough conditions without those issues, making them a sturdier choice.

A Real Problem in Brake Fluid Making

Here’s a story from the brake fluid world. A company was using a Screw Coated pump to distill oil for their brake fluid. But things went wrong. Tiny particles and moisture damaged the coating. The vacuum weakened, slowing down production. Batches took longer, and fixing the pump cost a fortune.

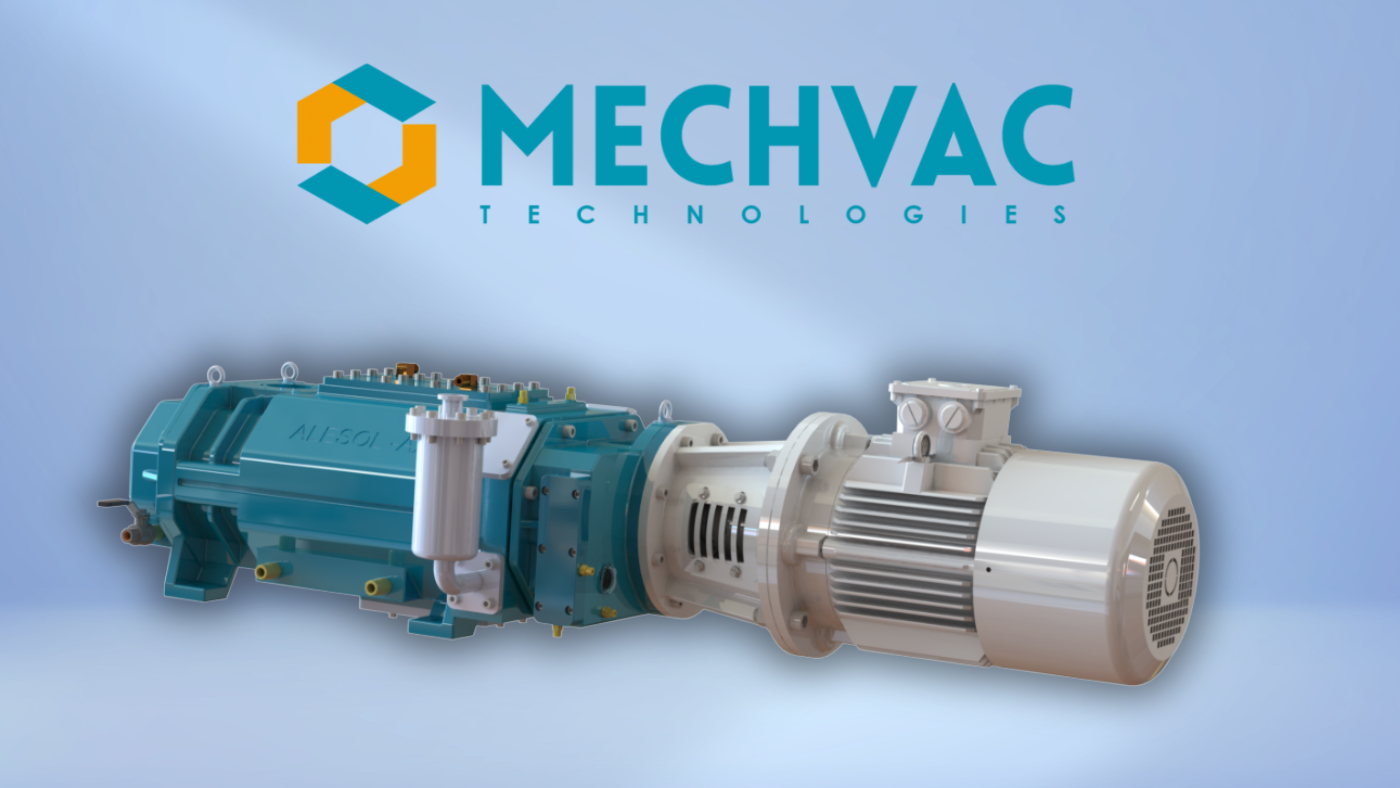

Finding a Fix

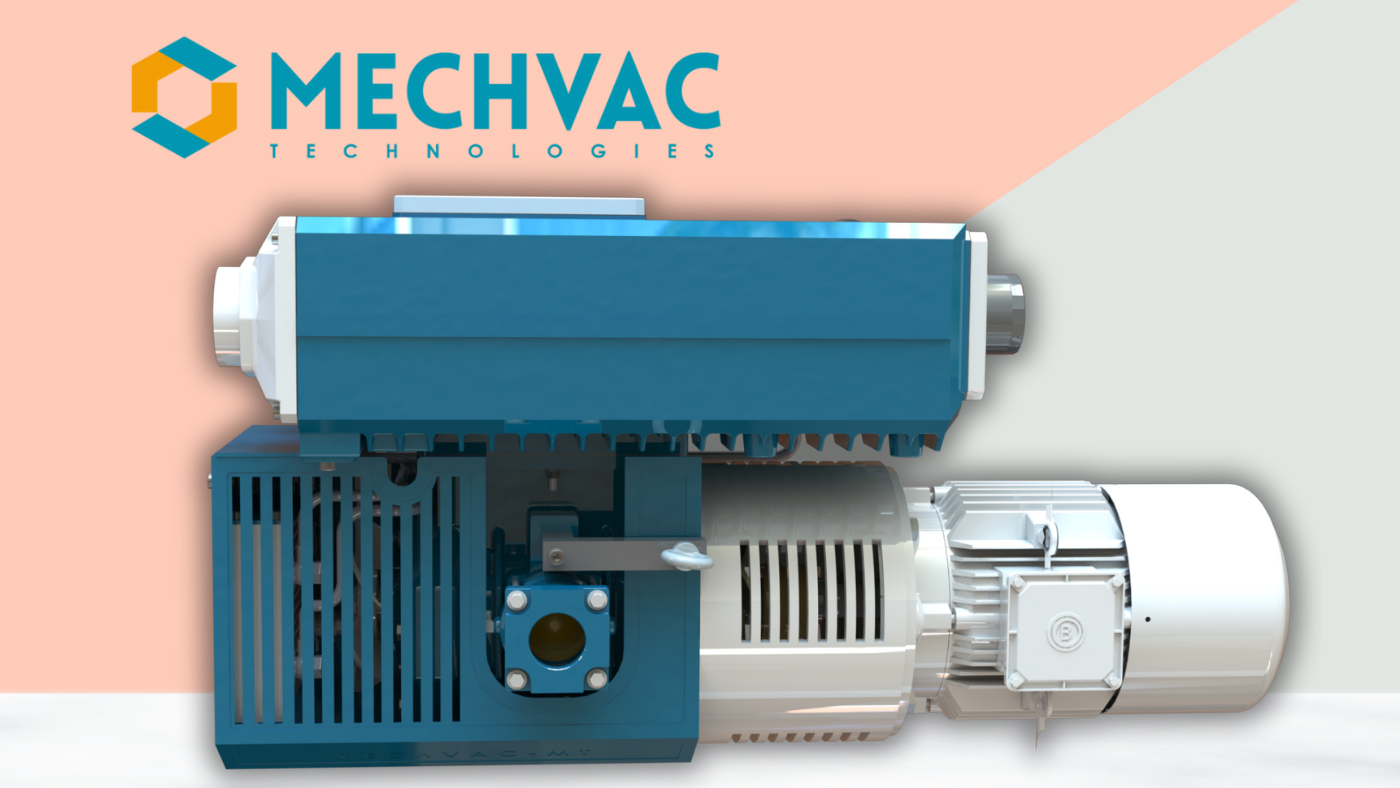

The company needed help, so they called in experts. The solution? Switch to a Dry Claw Vacuum Pump. The team added a flushing system to wash away particles and stop clogs. They also put in an insulated trap to catch junk before it reached the pump.

Amazing Results

Once the Dry Claw pump was installed, everything changed. Moisture drained away easily. The system ran at a super-low pressure 1 Torr, which is great for distillation. Batches finished faster, and repair bills shrank. The company couldn’t have been happier.

Why This Matters

This story shows how Dry Claw Vacuum Pumps can save the day in brake fluid production. They’re tough, efficient and cut down on problems that slow things down. For anyone in this industry, they’re a smart pick.

If you need a reliable partner to get the right pump, Mechvac Technologies has the know-how to make it happen. They’re experts at keeping production smooth and stress-free.