Enter the realm of precision heat treatment with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are meticulously engineered to excel in vacuum heat treatment applications, offering unmatched performance, reliability, and precision. From enhancing material properties to ensuring uniform heating, our vacuum pumps are the cornerstone of seamless and precise heat treatment processes across industries.

Were we use vacuum in Heat Treatment process ?

Yes, vacuum is commonly used in heat treatment processes for various materials to achieve specific properties or characteristics. Vacuum heat treatment involves subjecting materials to elevated temperatures in a controlled vacuum environment, rather than in a furnace filled with air or other gases. Here are some key applications of vacuum in heat treatment processes:

Annealing:

Vacuum annealing is a heat treatment process used to soften materials, relieve internal stresses, and improve machinability.

Annealing in a vacuum environment helps prevent oxidation and decarburization of the material surface, resulting in a cleaner and more uniform annealed product.

Hardening and Tempering:

Vacuum hardening and tempering are heat treatment processes used to increase the hardness and strength of materials such as steel.

Heating the material in a vacuum chamber followed by rapid quenching and subsequent tempering can result in improved mechanical properties without the risk of oxidation or distortion.

Brazing and Soldering:

Vacuum brazing and soldering processes involve joining metal components using a filler material that melts at high temperatures.

Operating in a vacuum environment ensures a clean and oxide-free surface, promoting strong and reliable joints between the materials.

Sintering:

Vacuum sintering is a process used to bond and densify powdered materials into solid components at high temperatures.

Sintering in a vacuum helps remove residual gases from the material pores, resulting in higher density and improved mechanical properties of the final product.

Degassing and Dehydration:

Vacuum heat treatment can be used for degassing and dehydration of materials, removing volatile substances and impurities to improve material purity and stability.

Surface Modification:

Vacuum heat treatment processes can be utilized for surface modification techniques such as carburizing, nitriding, and ion implantation, which enhance surface hardness, wear resistance, and corrosion resistance.

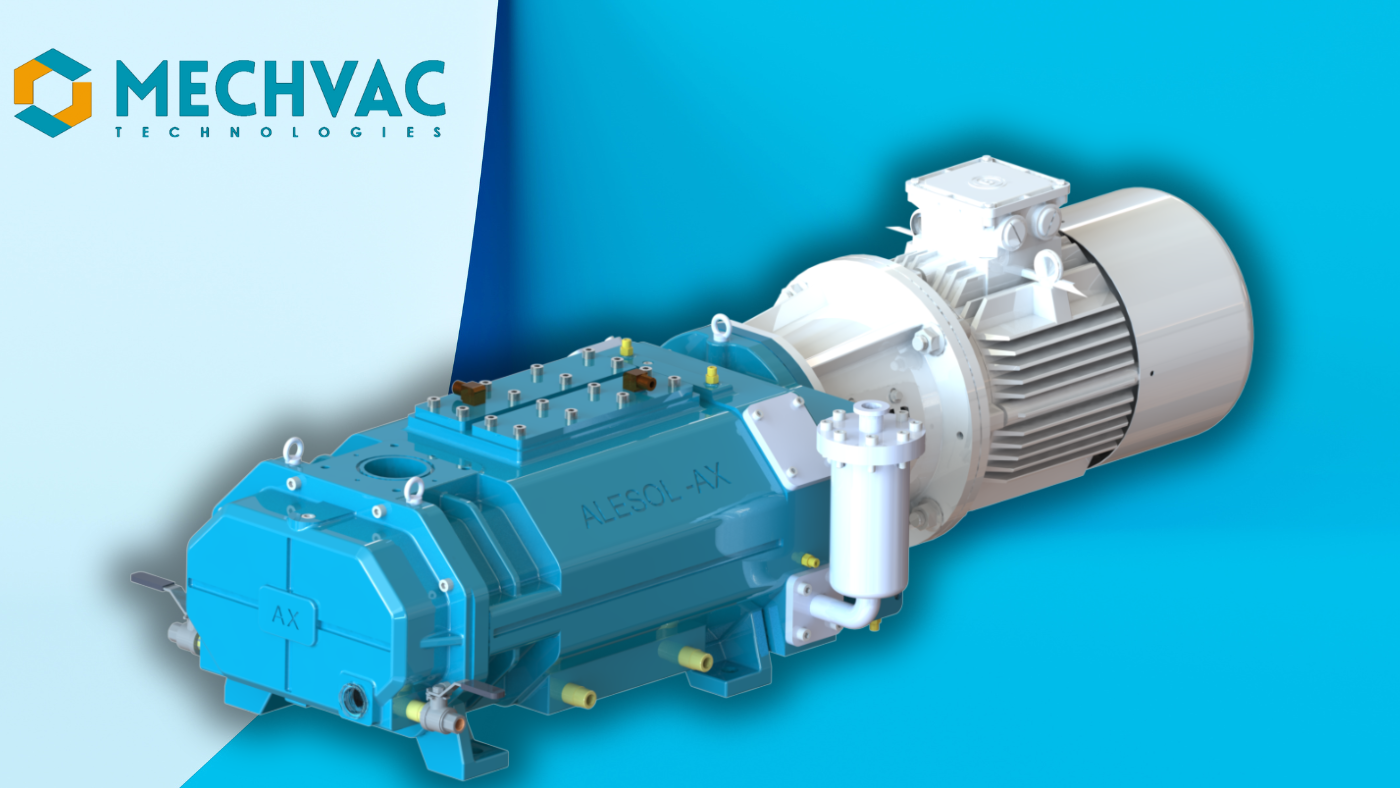

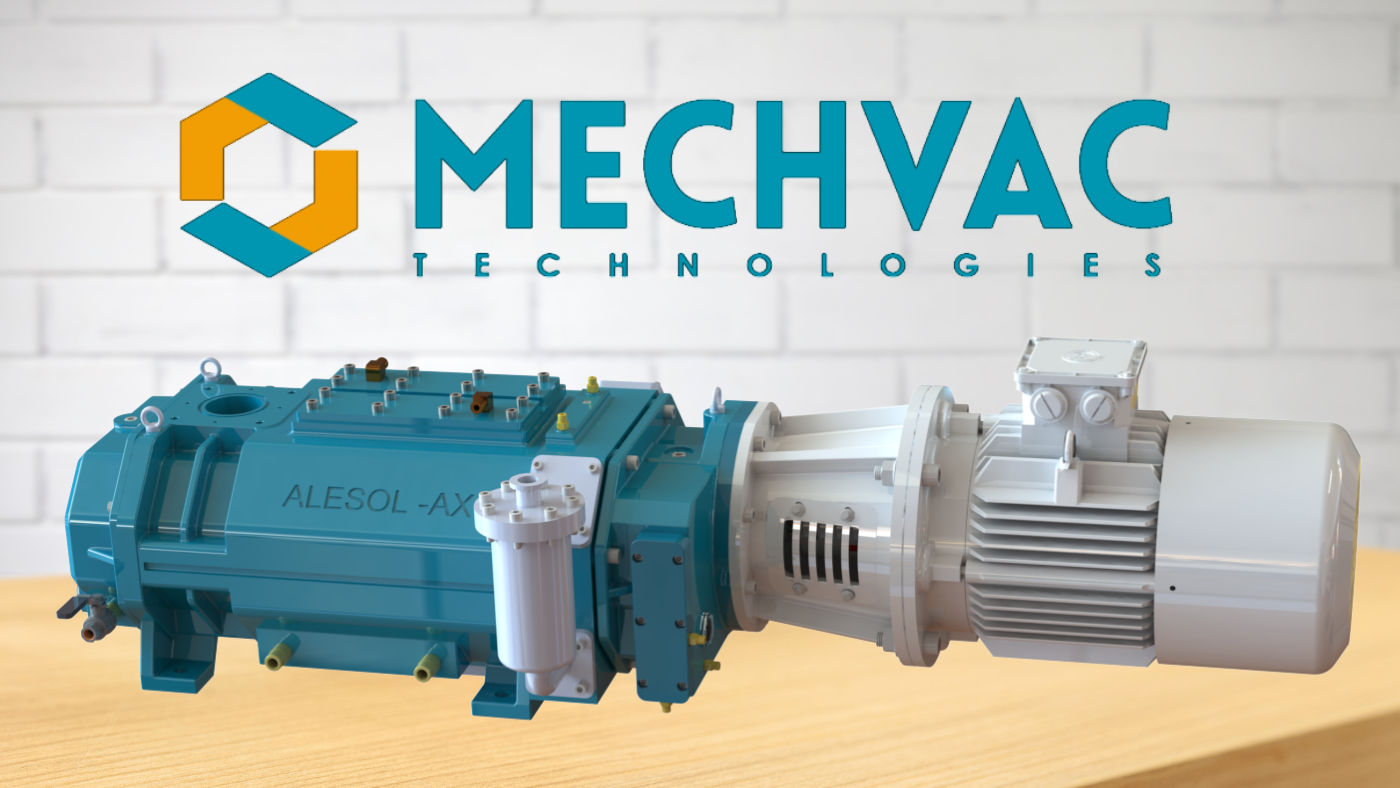

Introducing the MT Series, the unparalleled choice for vacuum heat treatment applications. Engineered with precision and innovation, the MT Series offers a host of benefits that redefine the heat treatment process:

Reduce Energy Consumption: With cutting-edge energy-saving technology, the MT Series optimizes power usage during vacuum heat treatment processes. By minimizing energy consumption, it not only lowers operational costs but also promotes environmental sustainability by reducing carbon emissions.

Save on Maintenance Costs: Built for durability and longevity, the MT Series requires minimal maintenance, resulting in reduced downtime and substantial savings on maintenance expenses. Its robust construction and reliable components ensure uninterrupted operation, allowing you to focus on productivity without worrying about frequent repairs.

Maximize Operational Reliability: The MT Series sets the standard for reliability, delivering consistent performance even in the most demanding heat treatment tasks. Its advanced features and high-quality engineering guarantee dependable operation, minimizing the risk of disruptions and optimizing productivity in your facility.

Increase Production Output: By enhancing efficiency and reliability, the MT Series accelerates vacuum heat treatment processes, leading to higher production outputs. Its superior performance streamlines operations, reduces cycle times, and boosts throughput, enabling you to meet production targets with ease and efficiency.

Protect the Environment: Committed to environmental stewardship, the MT Series incorporates eco-friendly features that minimize environmental impact and promote sustainable practices. By choosing the MT Series, you not only improve operational efficiency but also contribute to a cleaner, greener future for generations to come.

MT Series images