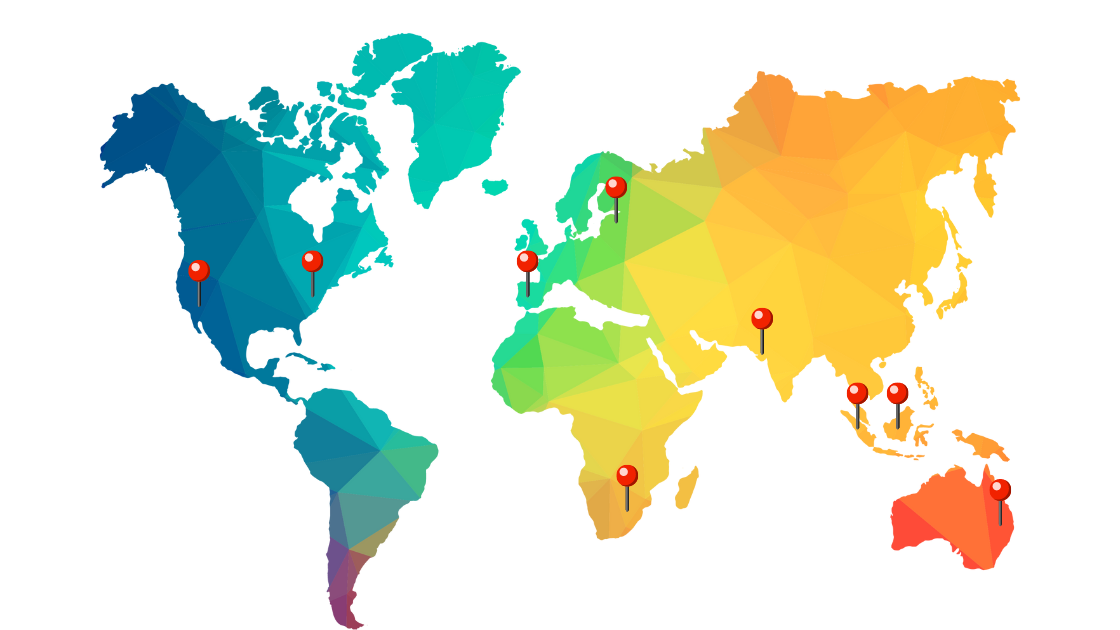

Experience the epitome of efficiency and precision in material handling with Mechvac Technologies Pvt Ltd’s vacuum pumps, proudly manufactured in India. Our vacuum pumps are meticulously engineered to excel in vacuum handling and lifting applications, offering unparalleled performance, reliability, and safety. From lifting heavy loads to delicate materials, our vacuum pumps are the cornerstone of seamless handling solutions across industries.

What is Vacuum Handling and lifting?

Vacuum handling and lifting, also known as vacuum lifting, is a method of material handling that utilizes vacuum technology to lift, move, and manipulate objects or materials without direct physical contact. This technique is widely used in various industries for tasks such as lifting heavy objects, handling delicate materials, and automating manufacturing processes.

Here’s how vacuum handling and lifting typically work:

Vacuum Generation: A vacuum pump creates a negative pressure (vacuum) within a suction cup or a vacuum gripper attached to a handling device, such as a robotic arm or a lifting apparatus.

Suction Cup Attachment: The suction cup or vacuum gripper is brought into contact with the surface of the object to be lifted. The negative pressure created by the vacuum pump creates an airtight seal between the suction cup and the object, holding it securely in place.

Lifting and Manipulation: Once the suction cup is securely attached to the object, the handling device activates, lifting or moving the object as required. The vacuum provides a strong grip on the object, allowing for precise and controlled manipulation.

Release: When the object is in the desired position or location, the vacuum pump can be deactivated or the pressure in the suction cup can be adjusted to release the object safely.

Vacuum handling and lifting offer several advantages:

Safe Handling: By securely gripping objects without the need for physical contact, vacuum lifting reduces the risk of damage to delicate materials and minimizes the potential for accidents or injuries to personnel.

Efficiency: Vacuum lifting systems can handle a wide range of materials, shapes, and sizes, making them versatile for various applications. They also enable faster and more efficient material handling compared to manual methods.

Automation: Vacuum lifting can be integrated into automated systems, such as robotic arms or conveyor systems, to streamline manufacturing processes and improve productivity.

Cleanliness: Since vacuum lifting systems typically do not use oils or greases for operation, they help maintain a cleaner working environment, particularly important in industries such as food processing or electronics manufacturing where cleanliness is critical.

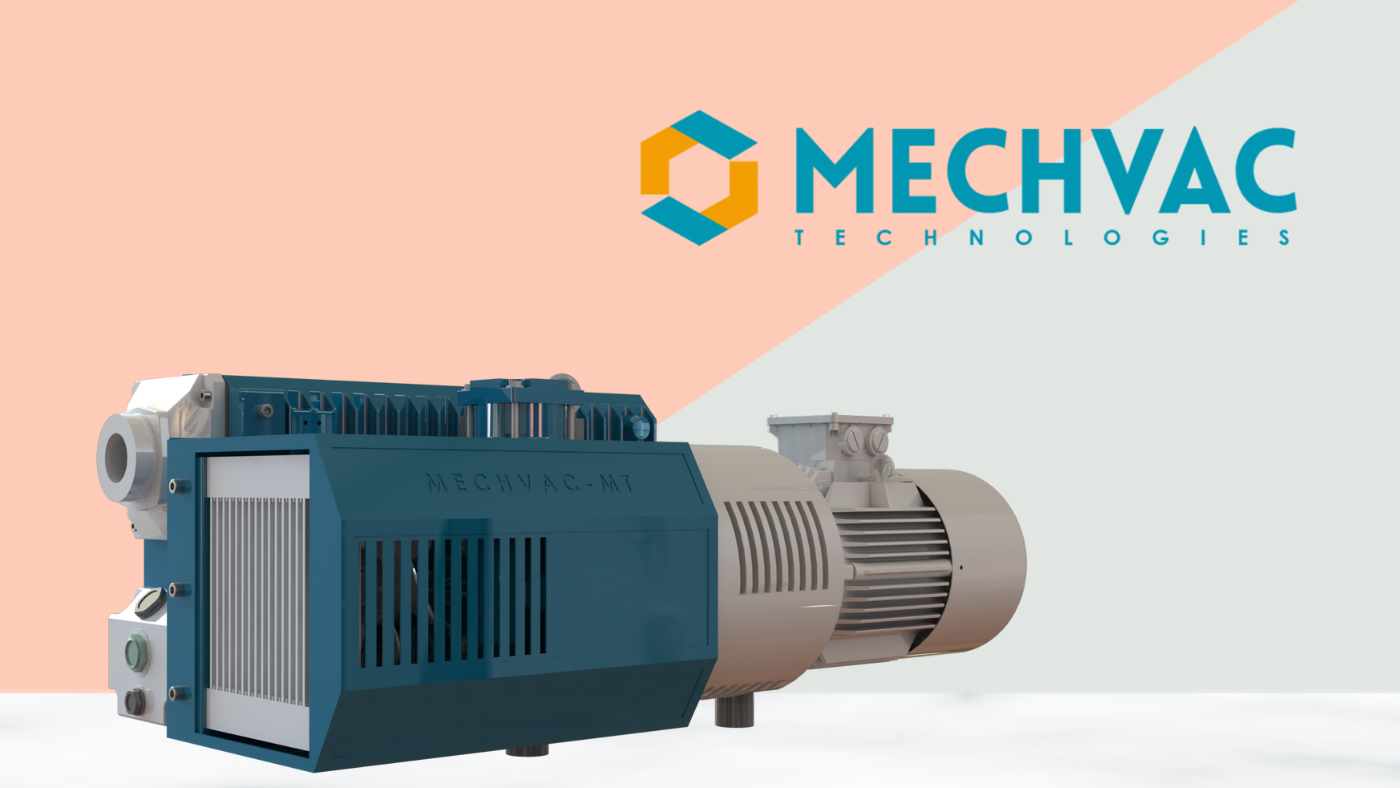

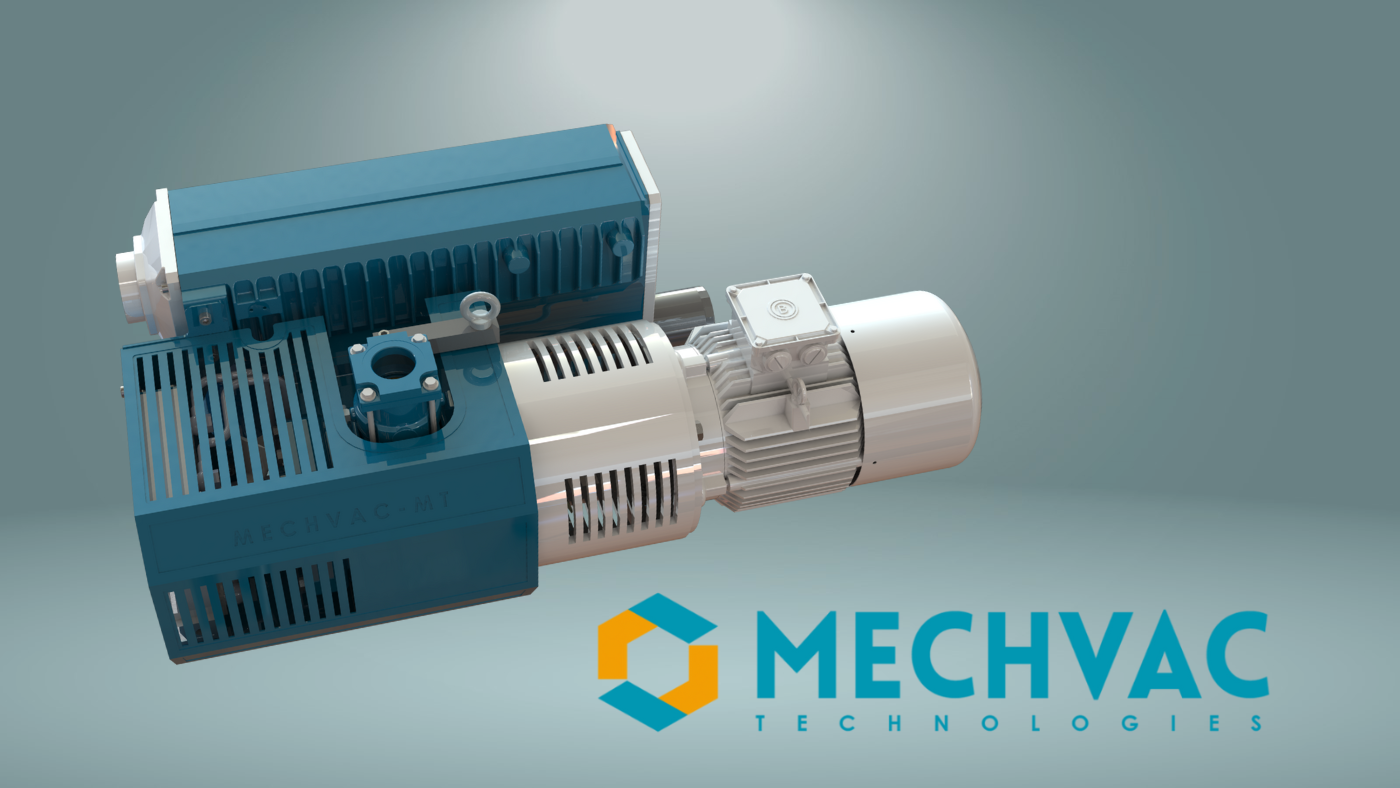

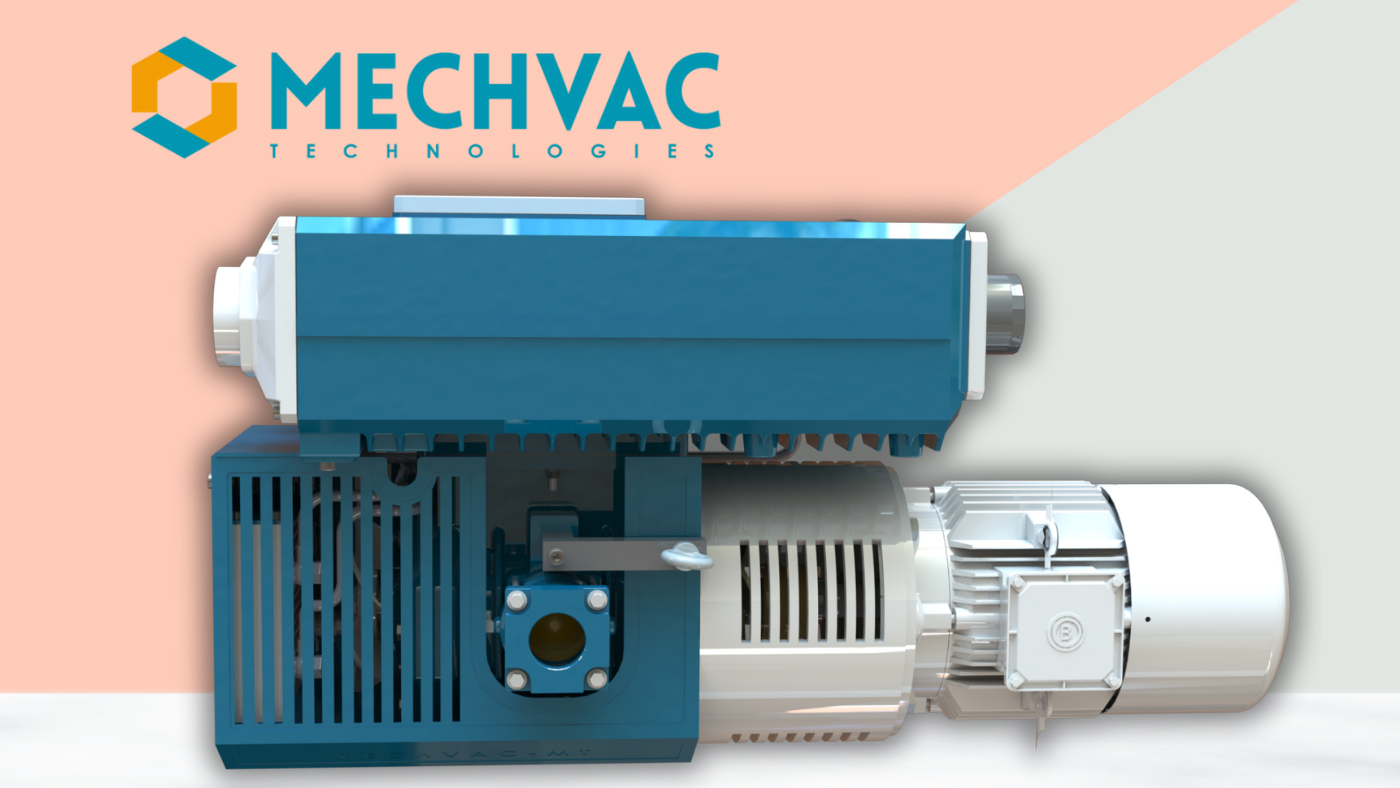

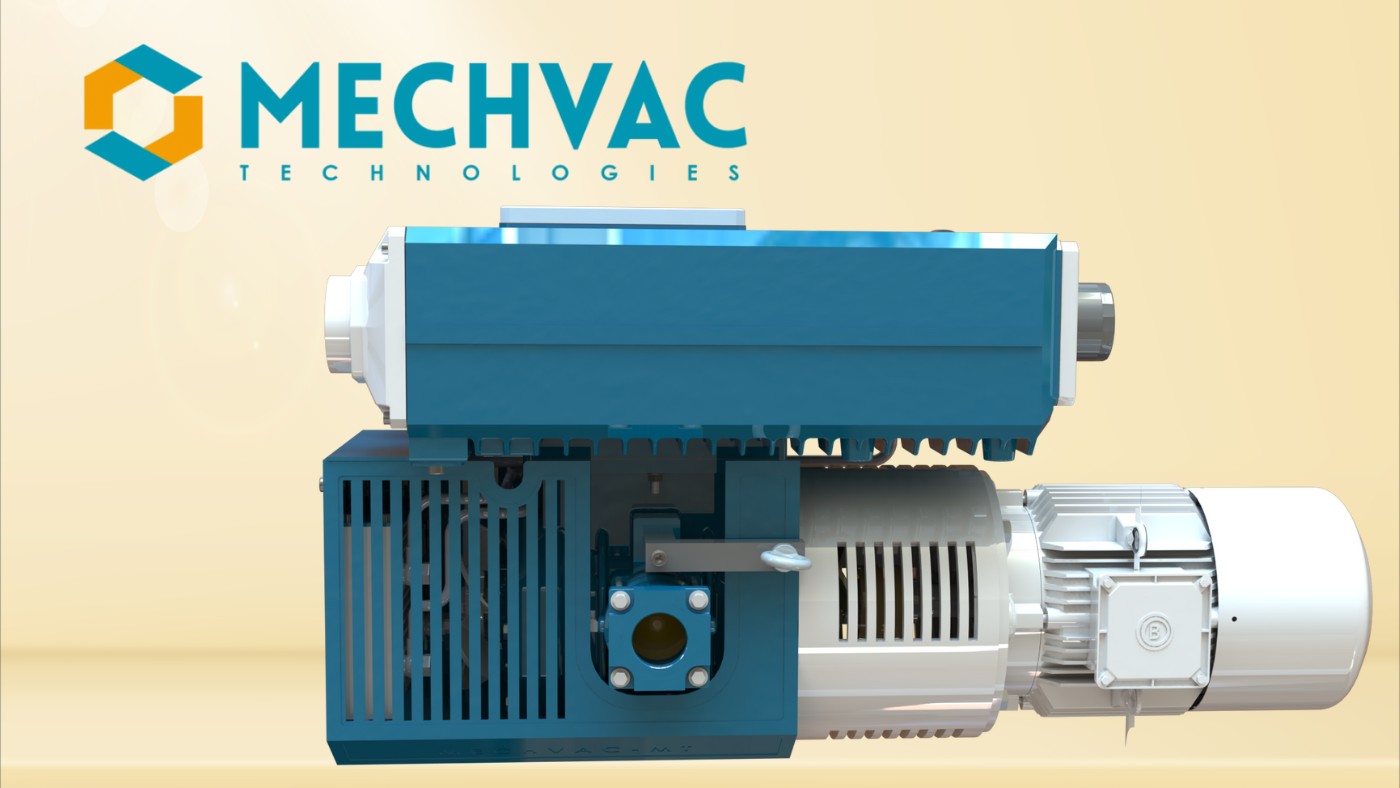

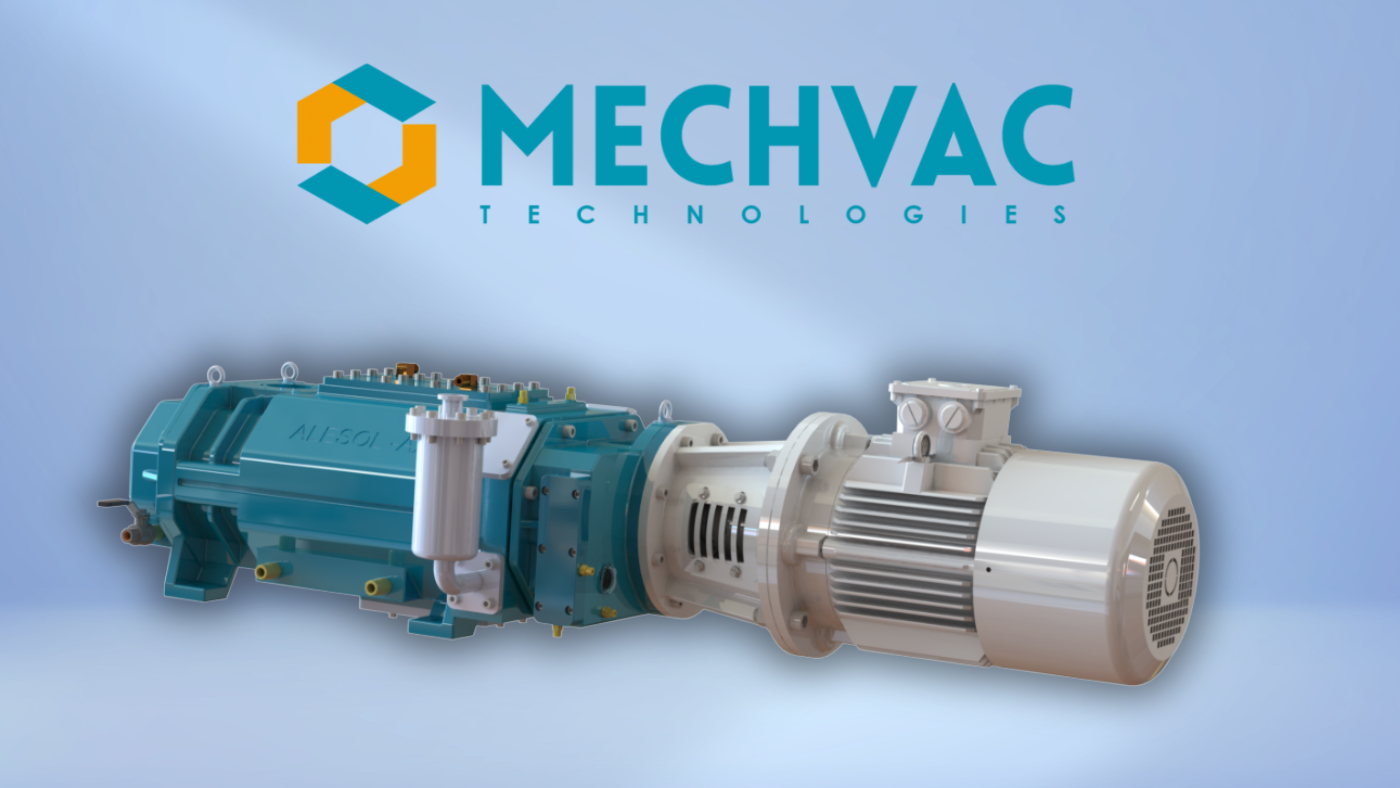

Introducing the MT Series, the ultimate solution for vacuum handling and lifting applications. Engineered with precision and innovation, the MT Series offers a comprehensive range of benefits that revolutionize your material handling processes:

Reduce Energy Consumption: With advanced energy-saving technologies, the MT Series minimizes power consumption during handling and lifting operations. By optimizing energy usage, it not only lowers operational costs but also contributes to a more sustainable environment by reducing carbon emissions.

Save on Maintenance Costs: Built for durability and longevity, the MT Series requires minimal maintenance, resulting in reduced downtime and substantial savings on maintenance expenses. Its robust construction and reliable components ensure uninterrupted operation, allowing you to focus on productivity without worrying about frequent repairs.

Maximize Operational Reliability: The MT Series sets the standard for reliability, delivering consistent performance even in demanding handling and lifting tasks. Its advanced features and high-quality engineering guarantee dependable operation, minimizing the risk of disruptions and optimizing productivity in your facility.

Increase Production Output: By enhancing efficiency and reliability, the MT Series accelerates material handling and lifting processes, leading to higher production outputs. Its superior performance streamlines operations, reduces cycle times, and boosts throughput, enabling you to meet production targets with ease and efficiency.

Protect the Environment: Committed to environmental sustainability, the MT Series incorporates eco-friendly features that minimize environmental impact and promote greener practices. By choosing the MT Series, you not only improve operational efficiency but also contribute to a cleaner, more sustainable future for generations to come.

MT Series images