Vacuum systems might not get the spotlight, but they’re the quiet champs keeping factories humming. Picture a world where your phone, car parts, or even that bag of chips didn’t rely on these clever machines. They work by creating low-pressure zones, which sounds basic, but trust this: it’s a total game-changer for industries everywhere. Let’s unpack why vacuum systems deserve some serious appreciation and how they make manufacturing smoother, cheaper, and safer.

Speeding Things Up

Think about a factory grinding to a halt because drying or packaging takes forever. Vacuum systems swoop in to save the day. They zap air out of food packages to lock in freshness fast, cutting down on spoiled goods. In electronics, they slap thin coatings onto microchips with lightning speed and pinpoint accuracy. Need to hoist a hefty glass pane or a metal slab? Vacuum lifters handle it without breaking a sweat, slashing time and effort. Efficiency shoots through the roof with these systems in play.

Pinching Pennies

Sure, vacuum systems might cost a chunk upfront, but they pay off big time. Less waste from slicker processes like filtration or drying means materials don’t end up in the trash. These machines are tough, too, needing barely any upkeep, which keeps repair bills low. And here’s the kicker: newer models sip electricity instead of guzzling it, trimming those pesky energy costs. Over months and years, the savings stack up, proving these systems are a manufacturer’s best buddy.

Keeping It Safe

Safety’s no joke in factories, and vacuum systems have that covered. Handling toxic powders or chemicals? They move that stuff without anyone getting close to the danger zone. Spills and fumes get sucked up quick, especially in places like woodworking shops or metal plants where dust could spark trouble. Cleaner air and fewer risks mean workers stay healthy, and the big safety regs get a thumbs-up.

Built to Fit

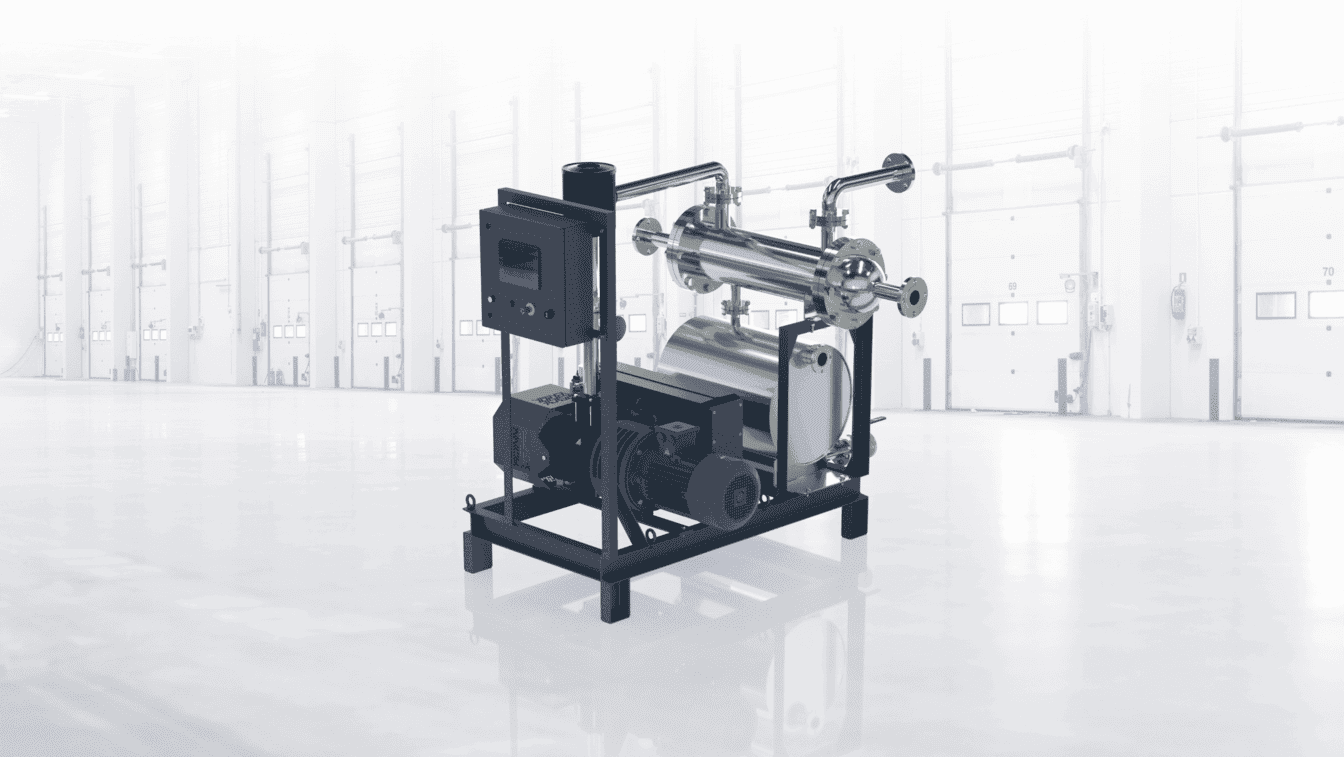

What’s awesome about vacuum systems is how they bend to fit any job. Small shop or sprawling plant, there’s a setup that works. Lifting giant sheets? Done. Keeping a sterile space for delicate tech? No problem. Manufacturers love this flexibility because it’s like having a custom tool for every task, making everything run like clockwork.

Jack of All Trades

Vacuum tech pulls off some wild stunts across industries. Food stays fresh longer thanks to airtight packaging. Drugs get freeze-dried in pharma labs to last for ages. Car makers test engines and brakes with vacuum tricks to ensure they won’t let anyone down. From snacks to sedans, these systems prove they can handle just about anything thrown their way.

Nailing Precision

Quality’s everything in manufacturing, and vacuum systems deliver. They create spotless, controlled zones free of dust or gunk, which is clutch for tech like phones or plane parts. Semiconductor plants use them to craft tiny, flawless bits for gadgets. Fewer slip-ups mean products come out shining, ready to impress.

Smarter Energy Use

Energy bills can sting, but vacuum systems ease the pain. New designs tweak power use on the fly with tricks like variable speed drives, so nothing gets wasted. Some even churn out a bit of energy during certain jobs. Less juice used equals more cash saved and a happier planet to boot.

Going Green

Speaking of the planet, vacuum systems are eco-warriors. Food lasts longer with vacuum packaging, so less ends up rotting in landfills. Chemical plants cut emissions and energy use with these systems humming along. Sustainability isn’t just a buzzword here; it’s baked into how these machines roll.

Quick Glance at the Magic

Here’s a rundown of how vacuum systems shine in different fields:

| Industry | Application | Benefit |

| Food | Vacuum packaging | Locks in freshness, speeds up the line |

| Electronics | Coating processes | Fast, precise work on tiny components |

| Pharmaceuticals | Freeze-drying | Keeps meds stable for the long haul |

| Automotive | Engine and brake testing | Makes sure cars run safe and strong |

| Material Handling | Vacuum lifters | Moves big stuff without a fuss |

What’s Next?

Vacuum tech’s future is buzzing with cool stuff. Smart systems tied to automation mean less downtime and sharper control. Fresh designs and materials keep pushing the limits, while the green focus keeps growing. As factories aim to stay lean and clean, vacuum systems will stay front and center.

Wrapping It Up

Vacuum systems are the backbone of modern manufacturing, cranking up efficiency, slashing costs, and boosting safety. They flex to fit any industry, from food to cutting-edge tech, and keep quality sky-high. With tech marching forward, these systems are getting sharper and greener, making them a no-brainer for anyone wanting to stay ahead. Factories leaning on vacuum tech aren’t just winning today; they’re building a better tomorrow.