What’s a Vacuum Pump?

Imagine you’re sealing up a bag of your favourite cookies to keep them crispy for weeks. Or imagine a factory making phone screens so clean you could eat off them. How do they pull it off? Enter the vacuum pump a cool gadget that whisks air and gases out of a sealed space to create a low-pressure zone, like a tiny slice of space right here on Earth.

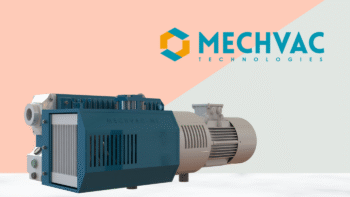

At Mechvac Technologies, we craft vacuum pumps that make these everyday miracles happen. Whether you’re keeping food fresh or building high-tech gear, our pumps have your back. If you’re new to this whole vacuum thing, no stress! This guide breaks it down in a fun, easy way, shining a light on the spinning wheel pump (aka rotary vane pump), a superstar in the vacuum world. We’ll also check out other pump types and their tricks, so you’ll know exactly what you need for your project.

Why These Pumps Rock

Vacuum pumps are like the quiet helpers behind tons of awesome stuff. They make spaces with less air pressure than the outside world, which is key for things like:

- Tech Toys: Keeping dust away when making computer chips or smartwatch screens.

- Snack Savers: Pulling air out of food packages so your chips or jerky stay fresh.

- Hospital Helpers: Powering tools for things like clearing airways or speeding up wound healing.

- Chilly Systems: Clearing out air and moisture from air conditioners before adding the cool juice.

Figuring out how these pumps tick can help you pick the perfect one, whether you’re tinkering at home or running a big operation.

The Pump Lineup

Pumps come in different styles, each with its own special sauce. Think of them like different ice cream flavors each one’s best for a certain vibe. Here’s the scoop:

- Scoop-and-Toss Pumps

These grab a handful of gas and chuck it out, like scooping sand out of a sandbox. They’re great for everyday jobs, like small science experiments or fridge fixes. - Whirlwind Pumps

These use super-fast blades or liquid sprays to shoo gas molecules away, like a gust of wind blowing leaves off your lawn. They’re for super-low-pressure tasks, like testing space gear. - Sticky-Catch Pumps

These nab gas molecules on special surfaces, like a cookie jar trapping crumbs. They’re for the deepest, cleanest vacuums, like in labs studying super-tiny stuff.

The spinning wheel pump, one of the scoop-and-toss types, is a crowd-pleaser because it’s simple and gets the job done. Let’s dive into its magic.

The Spinning Wheel Pump: How It Spins

The spinning wheel pump (rotary vane pump) is like the trusty skateboard of vacuum pumps easy to ride and ready for action. Here’s a fun way to see how it creates a vacuum.

The Setup

Imagine a big round cookie tin, called the shell, with a smaller spinning disc, called the wheel, inside it. The wheel’s not in the center it’s a bit off to one side, like a wobbly windmill. The wheel has slots that hold flat pieces, called flappers, which slide in and out as it spins. These flappers are made of tough stuff, like hard plastic or carbon, to keep up with the spinning.

A motor powers the wheel, making it whirl around. As it spins, the flappers are pushed outward by tiny springs or the spinning motion, so their edges stay snug against the shell’s inner wall. Because the wheel’s off-center, the spaces between the wheel and shell grow and shrink as they move around. These changing spaces are the key to the pump’s power.

How It Does Its Thing

Think of the pump as a windmill with little buckets that scoop up gas and toss it out. Here’s the play-by-play:

- Scooping Gas

As the wheel spins, a flapper passes the entry hole, where gas flows in. The space between two flappers gets bigger because of the wheel’s wobbly setup. This makes a low-pressure zone that pulls gas from the system into the pump, like sucking jelly through a straw. - Holding the Gas

The wheel keeps spinning, and the flapper moves past the entry, trapping the gas in the space between flappers. This gas gets carried along the shell’s wall, like kids holding hands on a carousel. - Squishing the Gas

As the space moves to the side where the wheel’s closer to the shell, it shrinks, squishing the gas like a baker flattening dough. - Tossing Gas Out

When the squished gas hits the exit hole, it’s pushed out through a flap into the air or another pump. This clears the space for the next scoop.

This cycle keeps spinning, pulling out more gas to make the system’s pressure drop lower and lower.

Why Oil’s a Star

Spinning wheel pumps need a bit of oil to shine. Here’s why it’s a big deal:

- Sealing Cracks: Oil fills tiny gaps between flappers and the shell, keeping gas from sneaking back in.

- Slick Moves: It keeps parts sliding smoothly, so they don’t wear out fast.

- Staying Cool: Oil soaks up heat from all that squishing, keeping the pump from getting too hot.

- Grabbing Gunk: It catches dust or stray bits, keeping the pump’s insides clean as a whistle.

You’ve got to swap the oil now and then, like watering a plant, to keep the pump happy. Using the wrong oil can mess things up, so check the pump’s guide.

One-Go vs. Two-Go Pumps

Some pumps are one-go, meaning they squish the gas once and push it out, hitting pressures around 0.1 millibar (mbar). Two-go pumps squish it twice, getting super-low pressures, like 0.001 mbar, which is awesome for fancier jobs, like drying delicate lab stuff.

Why the Wobbly Wheel Wins

The wheel’s off-center setup is the pump’s secret weapon. If it were centered, the spaces wouldn’t change, and no gas would move. The wobbly design makes spaces grow to pull gas in and shrink to push it out, like a bellows puffing air.

Picture the pump like a giant clock:

- At 12 o’clock, a flapper hits the entry, and the space starts growing, pulling in gas.

- From 12 to 3 o’clock, the space gets bigger, grabbing more gas.

- At 3 o’clock, the space is maxed out.

- From 3 to 6 o’clock, the space shrinks, squishing the gas.

- At 6 o’clock, the gas shoots out the exit.

- From 6 to 12 o’clock, the next space takes over.

This makes spinning wheel pumps great for jobs like sealing food bags or clearing air from cooling systems.

Other Pump Pals

Spinning wheel pumps are awesome, but other types have their own flair. Here’s a quick look at two others:

Water-Wall Pumps

These use a liquid, usually water, to trap and squish gas. A wheel with fixed blades spins inside a round case that’s partly filled with liquid. As it spins, the liquid gets pushed against the case’s walls, forming a wall of water, like a moat around a castle. The blades make pockets between them and the water wall, which scoop up gas, squeeze it, and toss it out.

These pumps are super tough, perfect for:

- Chemical Shops: Handling messy jobs like sorting liquids.

- Paper Mills: Squeezing water out of soggy paper pulp.

They can hit pressures around 30–50 mbar, depending on the liquid’s temp.

Clean-Spin Pumps

Clean-spin pumps skip oil or liquids in the pumping zone, keeping things spotless. They use setups like claw or twisty designs, where two wheels spin together to grab gas and move it out. In a claw pump, two claw-shaped wheels twirl opposite ways, scooping gas like a pair of dancers passing a ball.

These are great for:

- Tech Labs: Keeping oil fumes out of cleanrooms for chip-making.

- Food Packing: Staying extra clean for safety.

Clean-spin pumps can hit pressures from 50 mbar to 0.01 mbar, depending on the design.

Each pump’s got its own groove, so picking one depends on what you’re up to.

How to Pick Your Pump

Choosing a vacuum pump is like picking the right backpack it’s gotta fit your adventure. Here’s what to think about:

- How Low Do You Need?: For basic low-pressure jobs (above 1 mbar), a spinning wheel pump’s your buddy. For super-duper low pressures (below 0.001 mbar), whirlwind pumps are the way to go.

- How Fast?: Big setups need pumps that clear gas quick, measured in liters per minute.

- What’s the Gas?: Wet or gnarly gases need tough pumps, like water-wall ones.

- Keep It Clean?: For super-clean jobs, clean-spin pumps avoid oil messes.

- Upkeep Needs: Clean-spin pumps often need less TLC than oily ones.

- Budget Check: Find a pump that’s worth its price tag.

At Mechvac Technologies, we love helping you find the perfect pump. Give us a holler, and we’ll hook you up with one that fits like a glove.

Busting Pump Myths

Let’s clear up some confusion:

- Myth: Vacuums Pull Gas In Nope! The pump makes a low-pressure spot, and the outside air shoves gas in.

- Myth: All Pumps Are Twins Wrong! Each one’s built for different gigs.

- Myth: Lower Pressure’s Always Best Not true—some jobs just need a light vacuum, and overdoing it wastes dough.

Keeping Your Pump Happy

To make your pump last longer than your favorite hoodie:

- Fresh Oil: Swap oil in oily pumps to keep them purring.

- Right Oil: Use the stuff your pump’s guide suggests.

- Leak Hunt: Check for sneaky leaks that mess up your vacuum.

- Stay Sharp: Weird sounds or slow work might mean it’s time for a check-up.

Mechvac Technologies has your back with maintenance tips and fixes to keep things smooth.

A Quick Pump History

Vacuum pumps go way back to 1650, when Otto von Guericke whipped up the first one. He wowed folks by sealing two metal domes with a vacuum so strong that horses couldn’t yank them apart. That old-school stunt paved the way for today’s pumps, which help everything from space missions to your fridge.

Wrapping It Up

Vacuum pumps are like the wizards behind the curtain, creating low-pressure zones that make modern life awesome. The spinning wheel pump, with its wobbly wheel and clever flappers, is a champ for lots of jobs. Other types, like water-wall or clean-spin pumps, tackle special tasks, from messy gases to super-clean spaces.

At Mechvac Technologies, we’re stoked to help you find the right vacuum pump. Whether you’re just curious or ready to kick your project up a notch, our pumps and friendly advice are here for you. Swing by our website or drop us a line to see how we can make your ideas pop!

| Pump Type | What is Does | Great For | Why It’s Cool | What’s Tricky |

| Rotary Vane | Sliders scoop and squash gas | Labs, snack bags, fridges | Cheap, dependable | Needs oil, check-ups |

| Water-Ring | Liquid ring grabs and squeezes gas | Chemical plants, paper mills | Tough, loves wet stuff | Not super low pressure, needs liquid |

| No-Oil | Spinners move gas without oil | Tech cleanrooms, food packing | Super clean, less fuss | Costs more, fancy build |

| SpeedySpinner | Crazy-fast blades flick gas out | Space tests, research | Ultra-low pressure, fast | Pricey, needs backup |