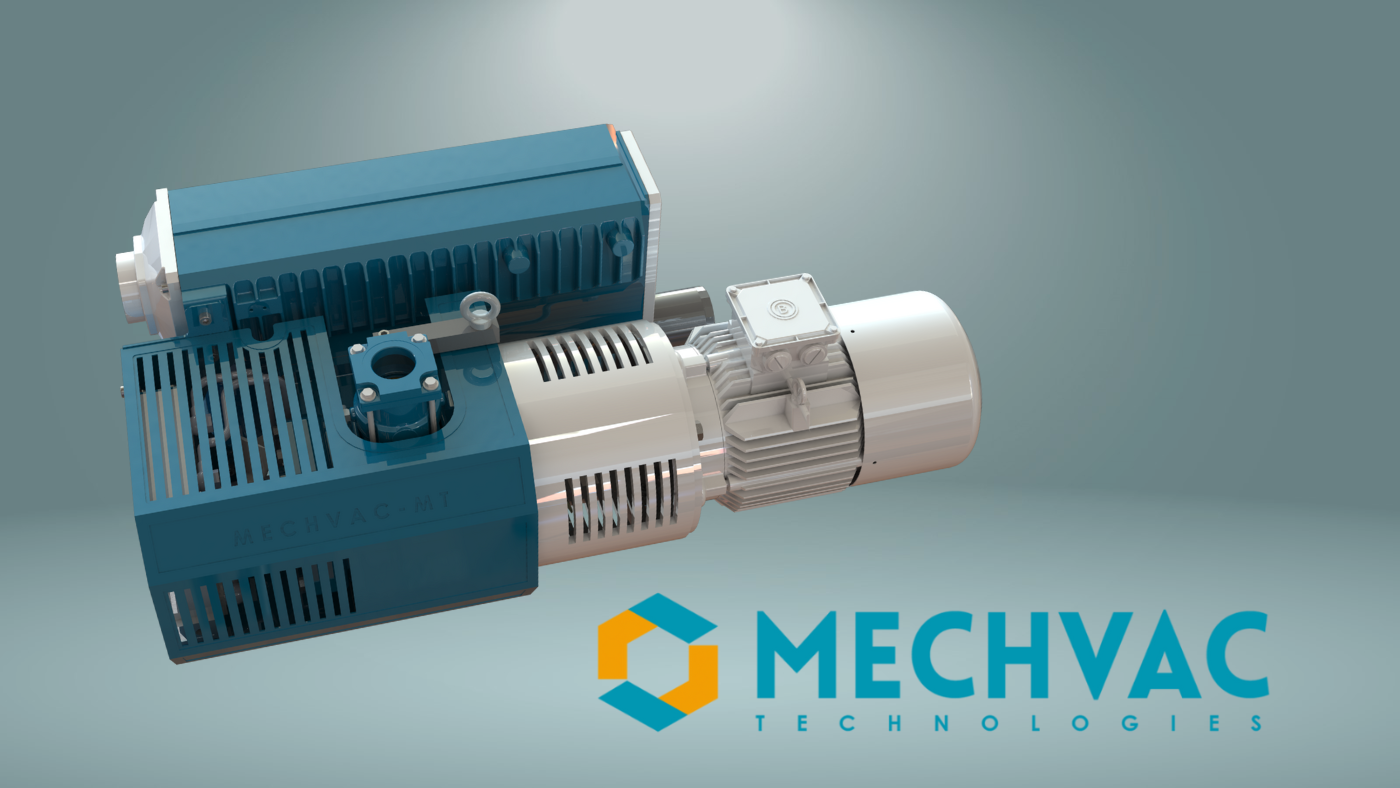

Oil-sealed vacuum pumps are super important in industries like packaging and electronics. To keep them working well and lasting a long time, you need to take care of them regularly. Good maintenance stops breakdowns, keeps things running smoothly, and saves you money on repairs.

In this blog, we’ll share easy tips to help you look after your oil-sealed vacuum pump.

Why Maintenance Matters

Taking care of your pump regularly is a big deal. It helps you spot small problems before they turn into huge headaches. A well-maintained pump runs better, which saves energy and cuts costs. Plus, it lasts longer, so you won’t need to buy a new one too soon.

Change the Oil Often

One of the best things you can do is change the oil regularly. The oil keeps the pump parts moving smoothly and helps seal them tight. But over time, the oil gets dirty or wears out, which can hurt the pump. Most makers say to change it every 500 to 2,000 hours of use.

Here’s how to do it:

- Let the pump cool down.

- Drain the old oil.

- Swap the oil filter if it’s dirty.

- Add fresh oil (check what the maker recommends).

Use the right oil and peek at it often. If it looks dark or cloudy, it’s time for a change. Oh, and toss out the old oil the right way!

Keep It Clean

A clean pump is a happy pump. Dust and dirt can make it overheat or wear out faster. Wipe down the outside regularly. Make sure the air intake and exhaust aren’t blocked. If you’re in a dusty spot, try adding filters or shields to keep junk out.

Watch How It’s Running

Keep an eye on your pump’s performance. Check the vacuum pressure to see if it’s hitting the right level. If it drops suddenly, there might be a leak or something wrong inside.

Feel the motor temperature, too If it’s too hot, there could be a lubrication or airflow issue. Also, watch the oil levels. If the pump is using more oil than normal, it might have a leak or worn parts.

Take Care of Seals and Gaskets

Seals and gaskets stop leaks from happening. Over time, they can wear out and mess up how the pump works. Replace them when the maker says to or if they look worn. Use good-quality parts and check for leaks often. If you spot oil around the seals, swap them out pronto.

Stop Contamination

Dust, water, or chemicals can sneak into your pump and cause trouble. To fight this, add an air intake filter to block dust and bits. In wet places, use a gas ballast to get rid of moisture. Check the oil often for signs and change it if it looks off.

Use It Right

Don’t push your pump too hard. Avoid running it at full power all the time. Keep the area around it clean and airy so it doesn’t overheat. Stick to the maker’s rules for temperature, pressure, and how long it should run. This keeps your pump healthy for the long haul.

Wrapping Up

Regular maintenance is the secret to keeping your oil-sealed vacuum pump in great shape. Change the oil, clean it up, watch how it runs, fix seals and gaskets, tackle contamination, and use it properly.

Doing these things will make your pump last longer and save you from pricey fixes. Need help or expert tips? Reach out to Mechvac Technologies; they’re pros at vacuum pump care!