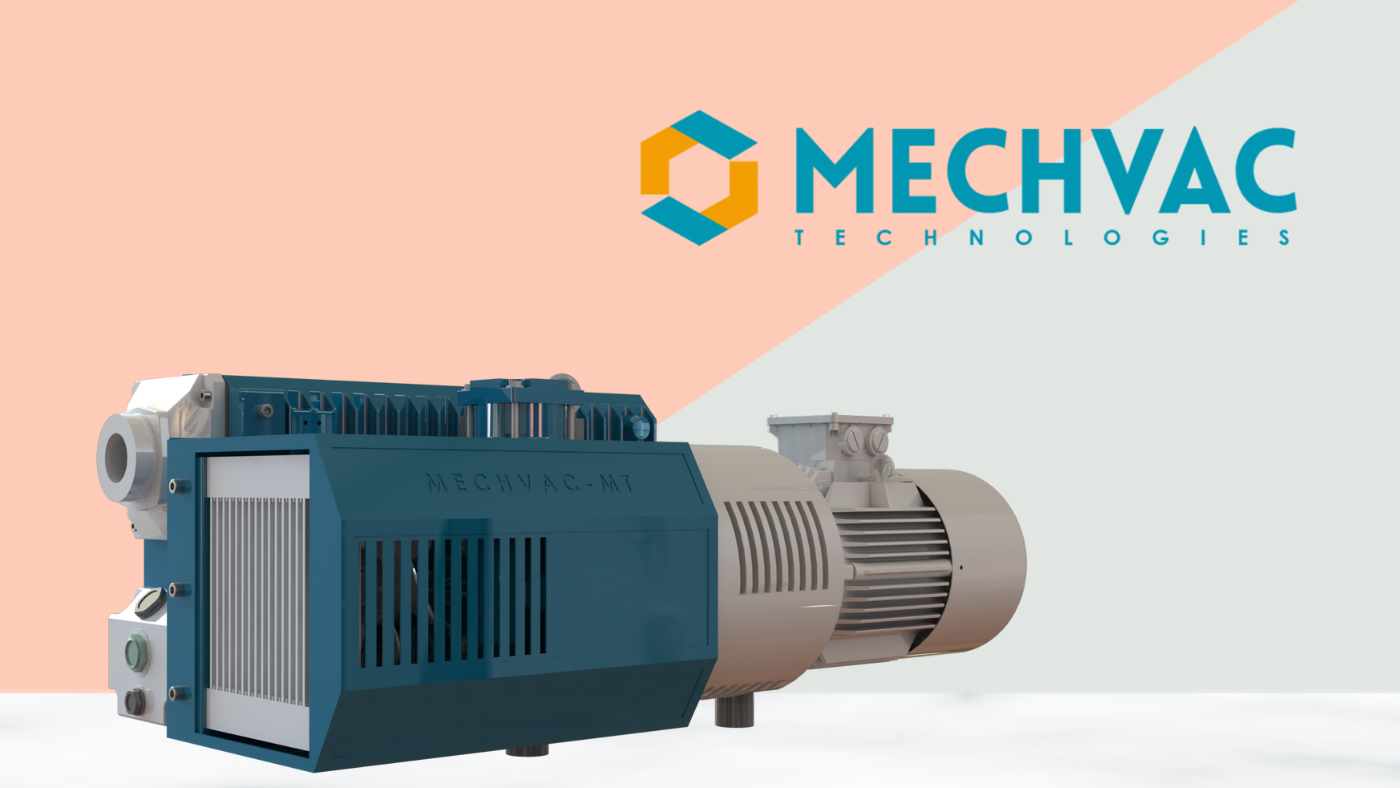

A hook and claw dry vacuum pump is a type of vacuum pump that removes air or gases from a sealed system to create a vacuum.

Unlike other pumps that might use oil or water, this one operates “dry,” meaning no additional fluids are required in its chamber.

Hook and claw dry vacuum pumps are widely used across different industries because they deliver a clean, dry vacuum that can be maintained efficiently.

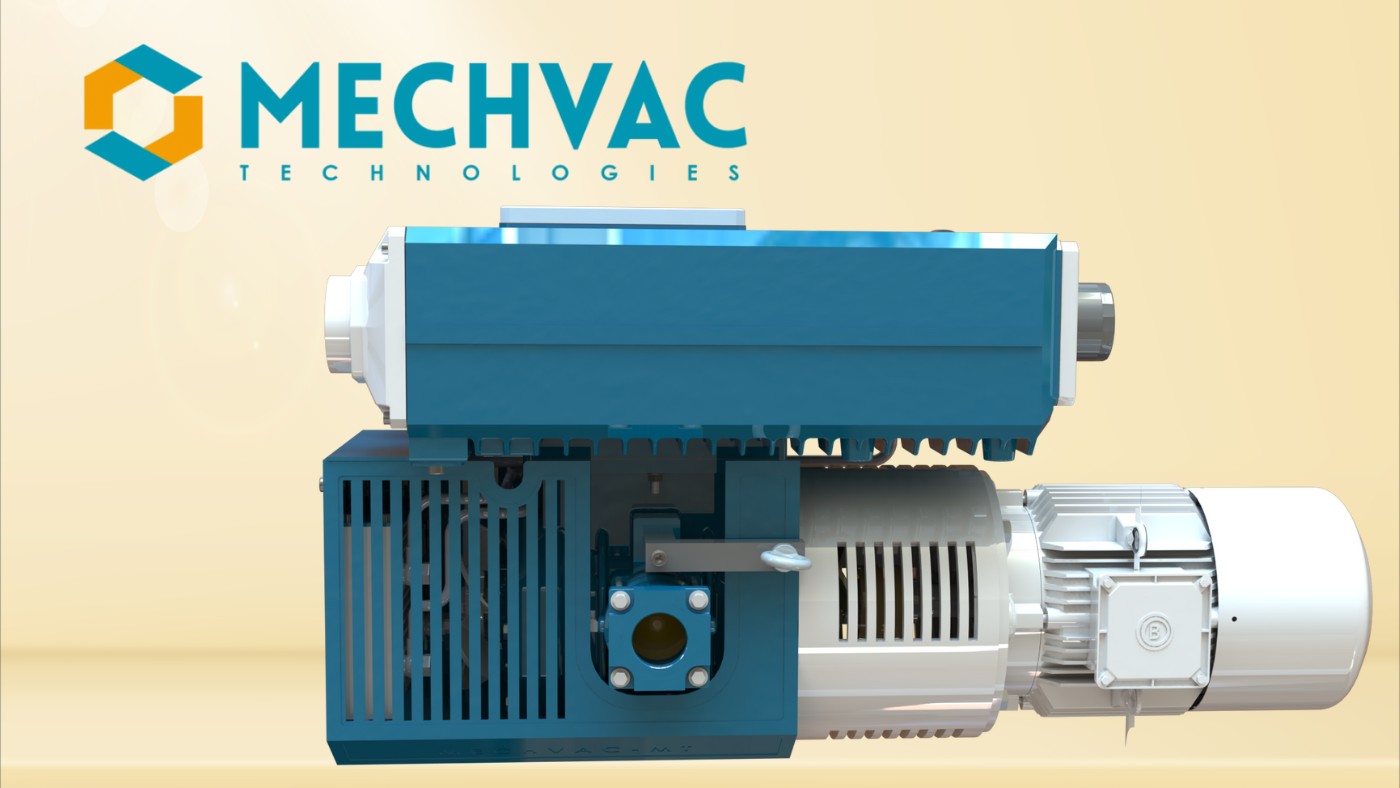

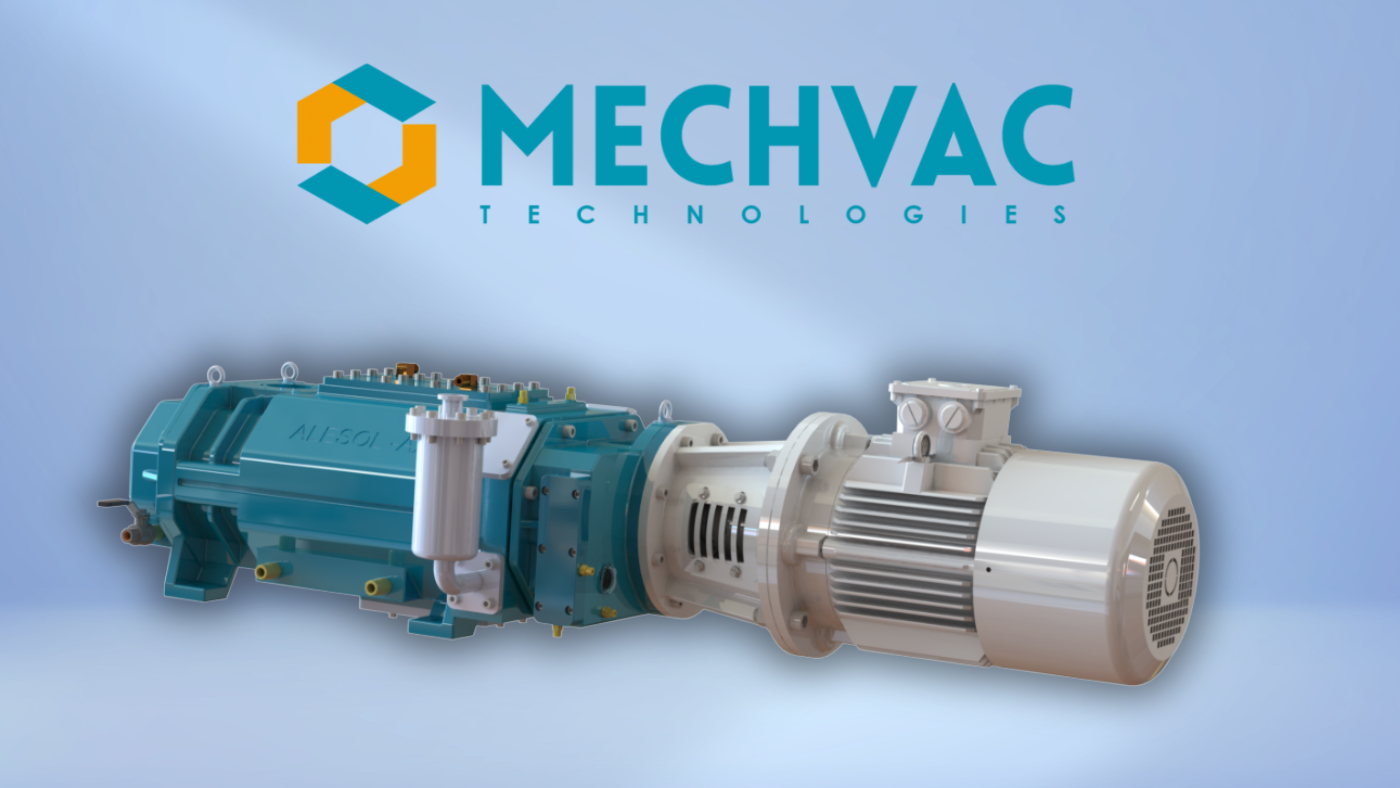

How Does a Hook and Claw Dry Vacuum Pump Work?

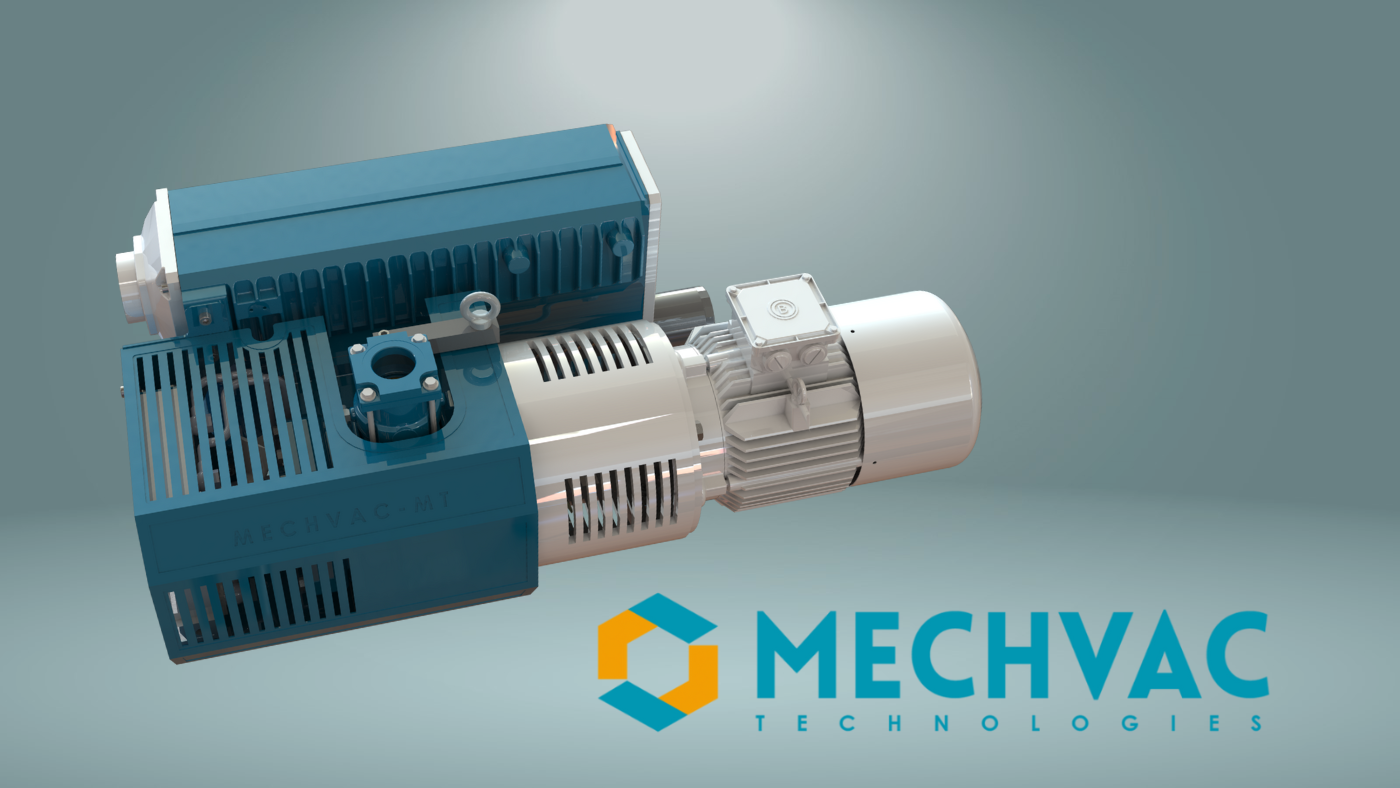

This pump works using two main components – the hook rotor and the claw rotor – which rotate in opposite directions. As they spin, these rotors trap and compress air molecules to create a vacuum.

The rotors’ unique shapes make this process efficient:

- Hook Rotor: Shaped with lobes like a hook or crescent, this rotor draws air molecules toward the inlet of the pump.

- Claw Rotor: Equipped with claw-shaped lobes, this rotor compresses the trapped air and directs it toward the pump’s outlet.

Together, these rotors operate within a sealed housing that prevents air from leaking in, ensuring a stable vacuum.

Key Features and Operating Principles of Hook and Claw Dry Vacuum Pumps

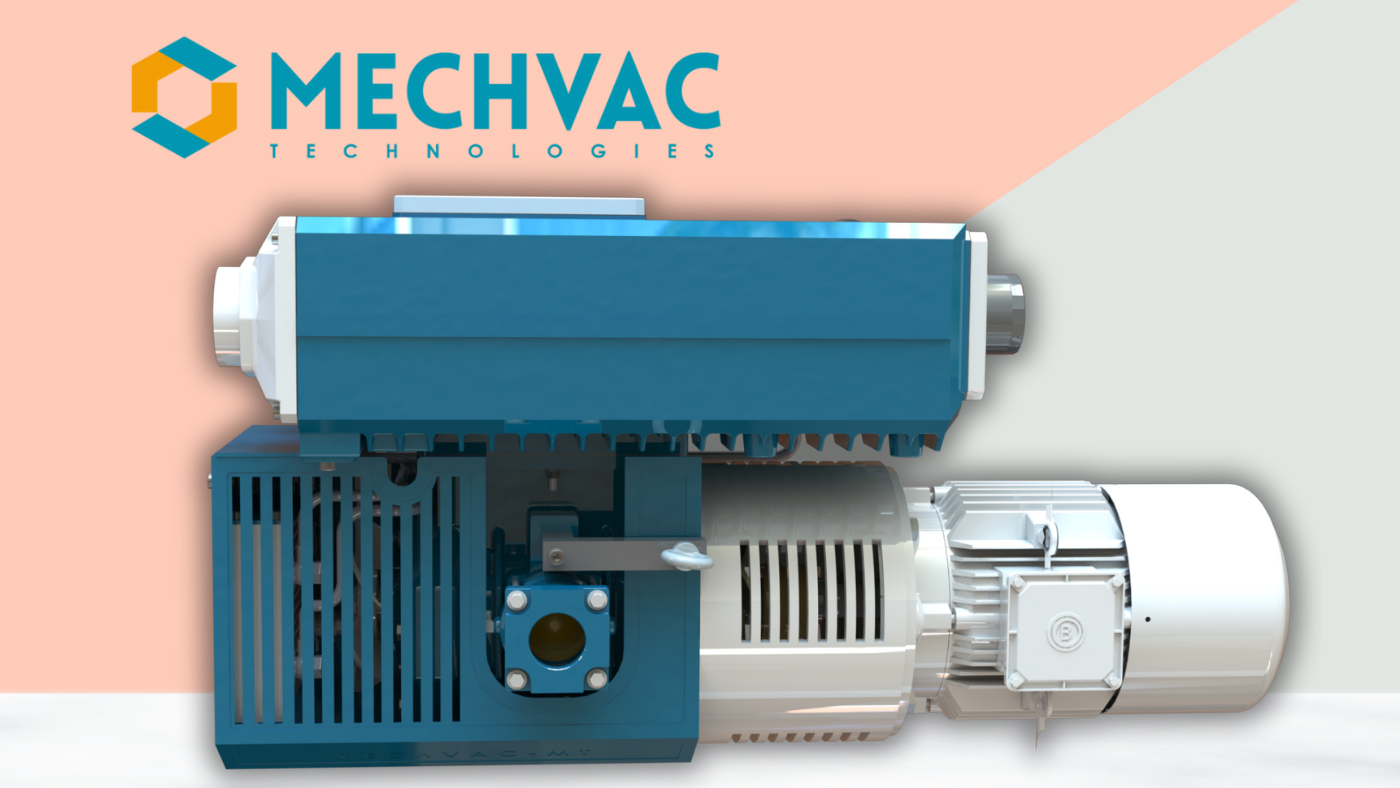

Hook and claw dry vacuum pumps are based on the positive displacement principle, meaning they continuously trap and compress air. Operating without oil or water, they are ideal for situations that demand a clean and dry environment. Here are some other important aspects of their operation:

- High Speed and Efficiency: These pumps run at high speeds and can handle pressures suitable for fast vacuum creation, especially useful in industries like electronics and semiconductor manufacturing.

- Low Noise and Vibration: With no oil or water to cause friction, these pumps have minimal noise and vibration, making them perfect for quieter environments such as research laboratories.

Advantages of Using Hook and Claw Dry Vacuum Pumps

- Clean and Dry Operation: Since no oil or water is used in the compression chamber, the pump produces a dry, uncontaminated vacuum. This is essential in industries like food processing and pharmaceuticals, where maintaining a clean environment is critical.

- High Efficiency: The pump’s high-speed capability makes it ideal for applications requiring a rapid vacuum, such as in electronics and semiconductor production.

- Quiet and Stable Performance: The design helps reduce noise and vibration, making it suitable for labs, research centers, and other environments that benefit from a quiet operation.

Where Are Hook and Claw Dry Vacuum Pumps Used?

The hook and claw dry vacuum pump is versatile and widely used across multiple industries:

- Food and Pharmaceuticals: It’s oil-free, which prevents contamination, making it suitable for food packaging, vacuum drying, and other sanitary applications.

- Semiconductor and Electronics Manufacturing: High-speed, efficient vacuum creation is essential for these fields.

- Laboratories and Research Facilities: The quiet, stable operation is perfect for sensitive research tasks.

- Vacuum Packaging and Distillation: The pump works well for packaging processes and distillation tasks due to its clean and dry vacuum capabilities.

The pump can also handle gases like nitrogen, argon, and air, making it a highly adaptable solution for various applications.

Conclusion: Why Choose a Hook and Claw Dry Vacuum Pump?

The hook and claw dry vacuum pump is a valuable asset in many industries thanks to its clean, oil-free operation, low noise, and high efficiency.

From food and pharmaceutical processing to advanced electronics manufacturing, this pump offers reliable performance without the need for oils or lubricants.

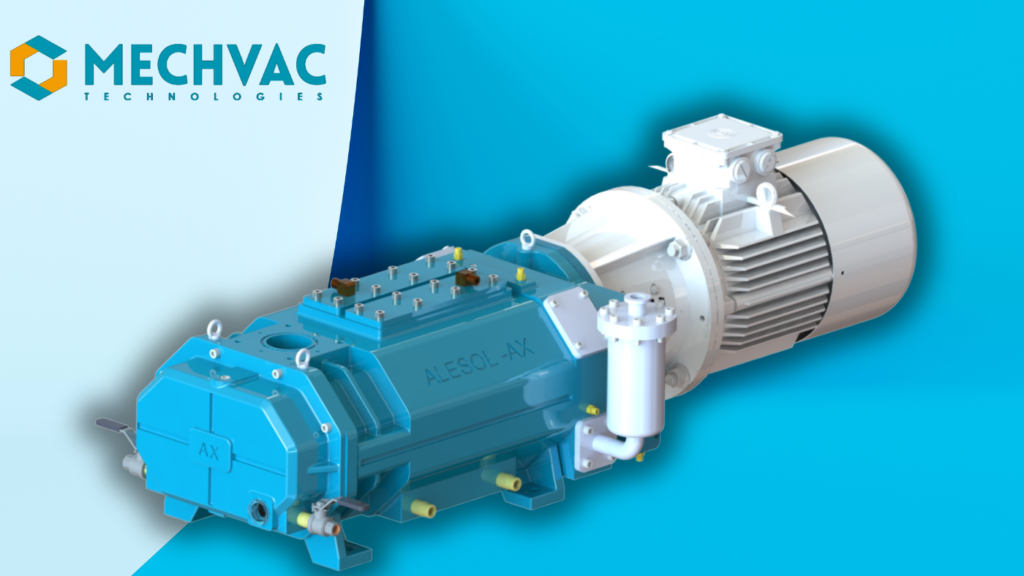

How Mechvac Technologies Can Help: At Mechvac Technologies, we specialize in providing high-quality hook and claw dry vacuum pumps that are designed for durability, efficiency, and ease of use.

Whether you’re in manufacturing, research, or food processing, we deliver solutions to meet your vacuum requirements with products that you can trust to perform.