Vacuum pumps are critical for various industrial and lab processes, from chemical processing and food packaging to vacuum-assisted manufacturing.

They create the vacuum environment needed for essential tasks like distillation, filtration, and heat transfer.

However, to get the most from your vacuum pump, it’s crucial to know its strengths and limitations. More importantly, understanding the warning signs and common reasons for vacuum pump failure can help prevent breakdowns before they happen.

When vacuum pumps fail, it can lead to costly production delays or equipment damage. That’s why it’s vital to recognize and address issues early.

Common mistakes like overloading, running dry, or exposure to damaging substances can also lead to failure.

Maintenance oversights—such as not lubricating bearings or neglecting to check for leaks—can have a similar effect.

Recognizing Vacuum Pump Warning Signs

Recognizing the warning signs of vacuum pump failure allows you to act quickly, avoiding costly downtime and potential equipment damage. Here are some signs to watch for:

- Unusual Noises: Grinding, knocking, or rattling sounds could mean issues with bearings, gears, or other internal parts that need immediate attention.

- Decreased Performance: If you notice a drop in pumping speed, longer cycle times, or lower vacuum quality, it could mean the pump isn’t operating as efficiently as it should. Regular performance monitoring can help spot these deviations early.

- Leaks: Leaks can develop in various parts of the pump, like the seals, valves, or hoses. This can cause pressure drops, efficiency loss, and performance issues. Regularly check for leaks and fix them right away.

Common Reasons for Vacuum Pump Failure

Several factors can lead to vacuum pump failure. By understanding these, you can help prevent potential issues:

- Insufficient Maintenance: Regular cleaning, lubrication, and part replacement are essential for keeping vacuum pumps in good condition. Neglecting these tasks can lead to damage and reduce pump efficiency.

- Improper Installation: Misalignment, poor connections, or lack of support can cause issues like leaks, vibrations, and overheating, which all impact pump performance and longevity.

- Operational Mistakes: Overloading, running the pump without lubrication, or exposure to harmful substances can cause serious damage and reduce efficiency. Following the manufacturer’s usage guidelines can help avoid these issues.

- Contamination and Wear: Exposure to contaminants or prolonged wear can cause mechanical problems, such as damaged gears or worn-out bearings, reducing the pump’s performance and lifespan.

Tips for Optimal Vacuum Pump Use

Here’s how you can keep your vacuum pump running smoothly:

- Follow Installation Guidelines: Proper setup is key. Ensure secure connections, alignment, and support to avoid leaks and overheating. Always refer to the manufacturer’s instructions during installation.

- Stick to a Maintenance Schedule: Routine inspections, cleaning, lubrication, and replacing parts when needed can prevent breakdowns. Proactive maintenance keeps your pump functioning efficiently.

- Adhere to Safe Usage Practices: Operate within recommended parameters, avoid overloading, and protect the pump from damaging substances. Regular monitoring will help identify any potential issues early on.

Avoid These Common Mistakes When Using a Vacuum Pump

While best practices are essential, it’s also important to avoid mistakes that could damage your pump:

- Running the pump without sufficient lubrication

- Overloading beyond recommended capacity

- Exposing the pump to harmful chemicals or moisture

- Ignoring signs of performance decline

Setting Up Vacuum Pumps the Right Way

Correct installation is crucial for optimal performance and lifespan. Here’s a checklist for setting up your vacuum pump:

- Carefully review the manufacturer’s instructions for specific setup requirements.

- Prepare a clean, dry installation site free of contaminants.

- Align and secure the pump, ensuring it is stable and properly grounded. Make sure electrical connections are safe and meet the required standards.

- Test the pump after installation to check for leaks, unusual vibrations, or overheating.

Conclusion

Understanding and recognizing the signs of vacuum pump failure can prevent significant disruptions and repair costs.

With regular maintenance, proper installation, and safe operational practices, you can extend the life of your vacuum pump and keep your operations running smoothly.

How Mechvac Technology Can Help

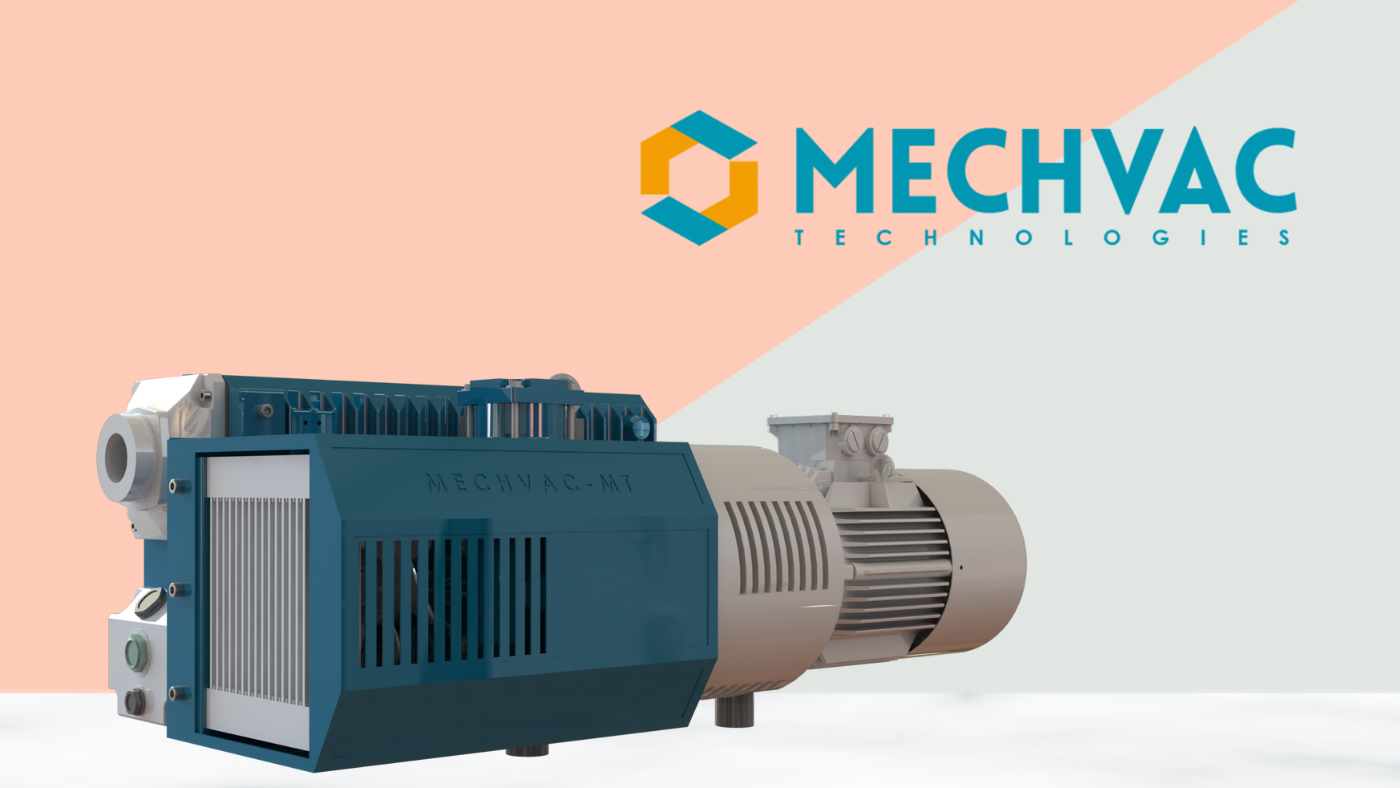

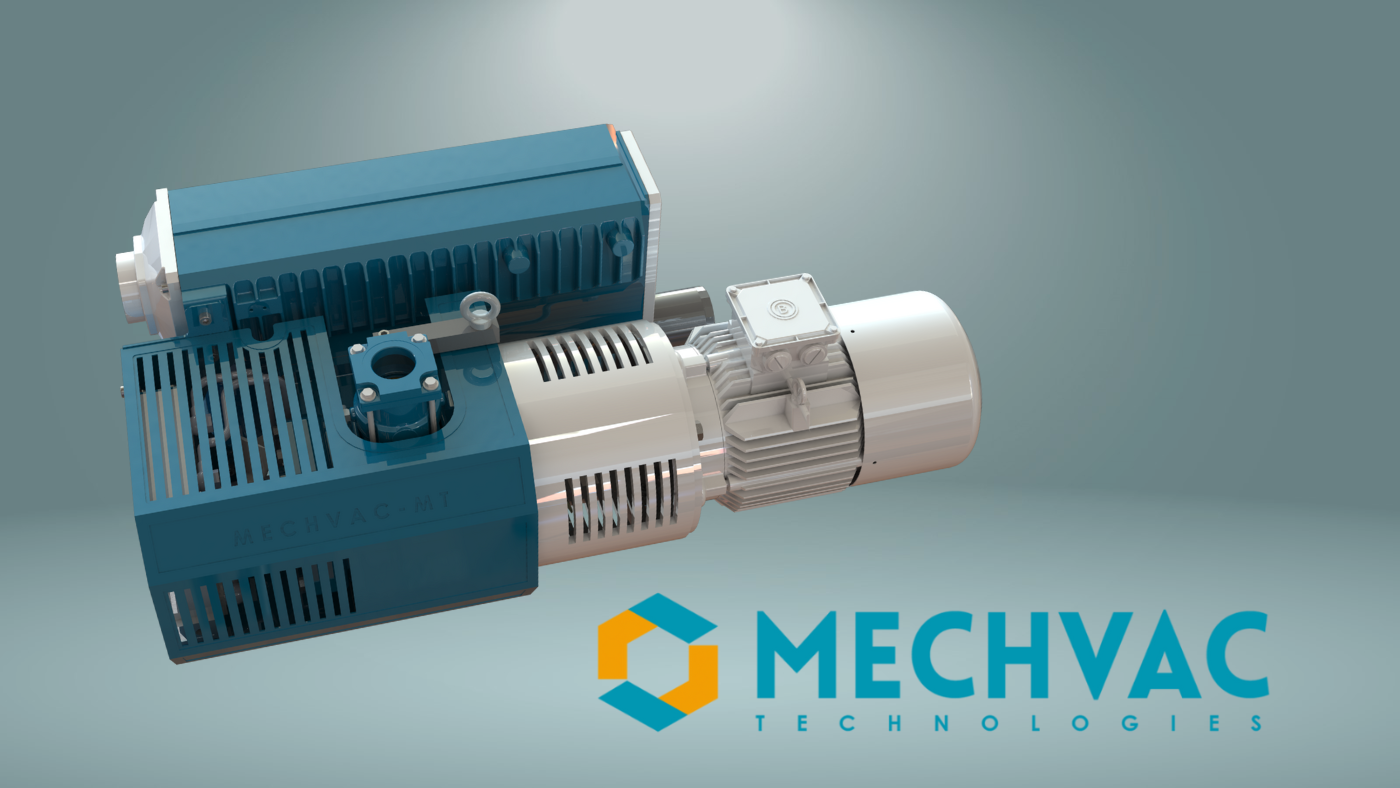

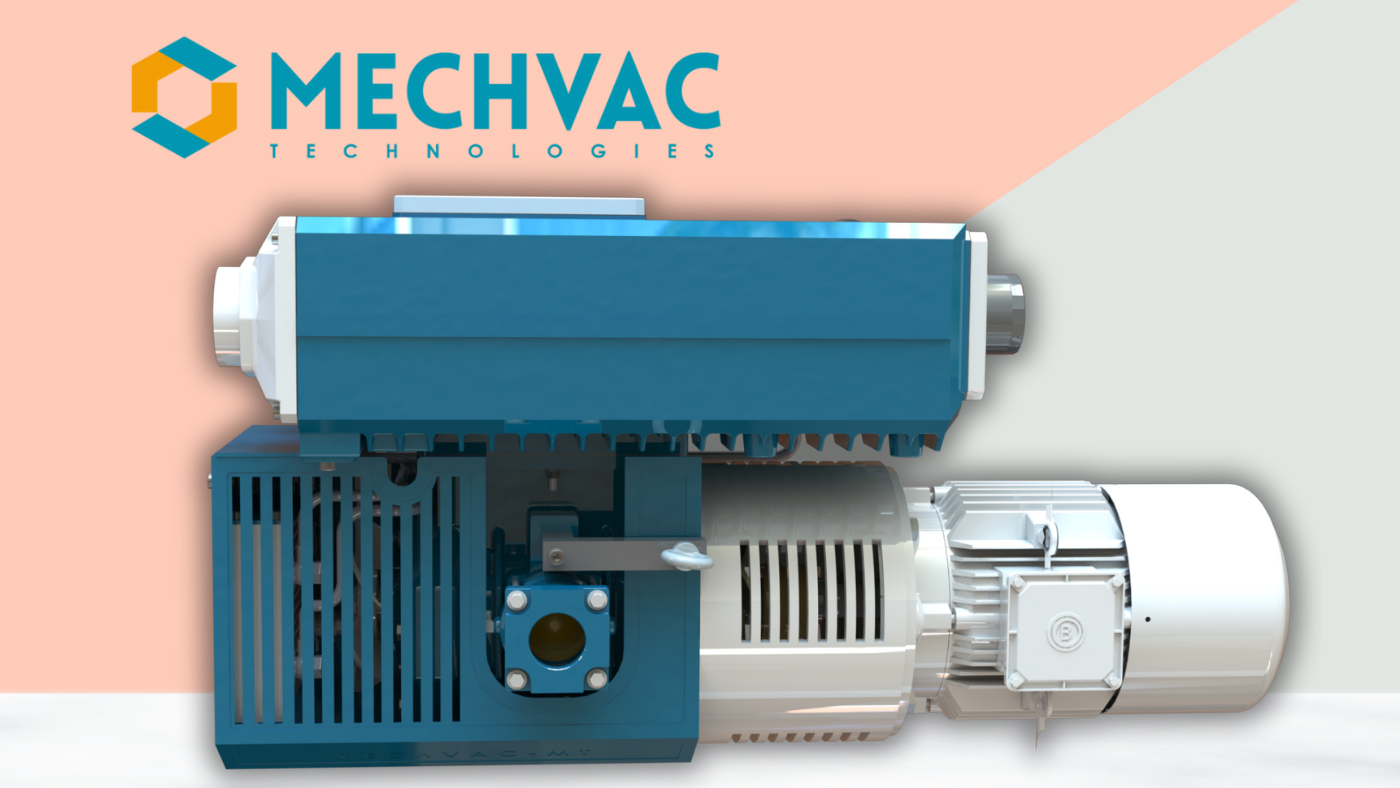

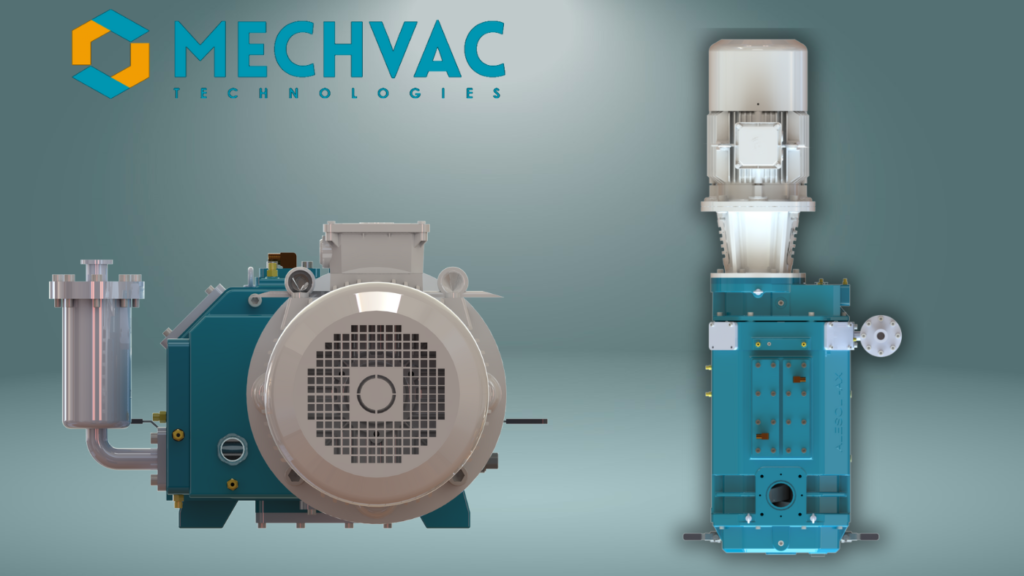

At Mechvac Technologies, we offer high-quality vacuum pumps and expert support to meet your specific needs.

Our team is here to help you select the right equipment and provide guidance on maintenance and installation to maximize performance and prevent downtime.

Reach out to us for reliable, world-class vacuum solutions and let us help you achieve the efficiency you need.