When it comes to industries that require removing gas from a sealed system, vacuum technology plays a vital role.

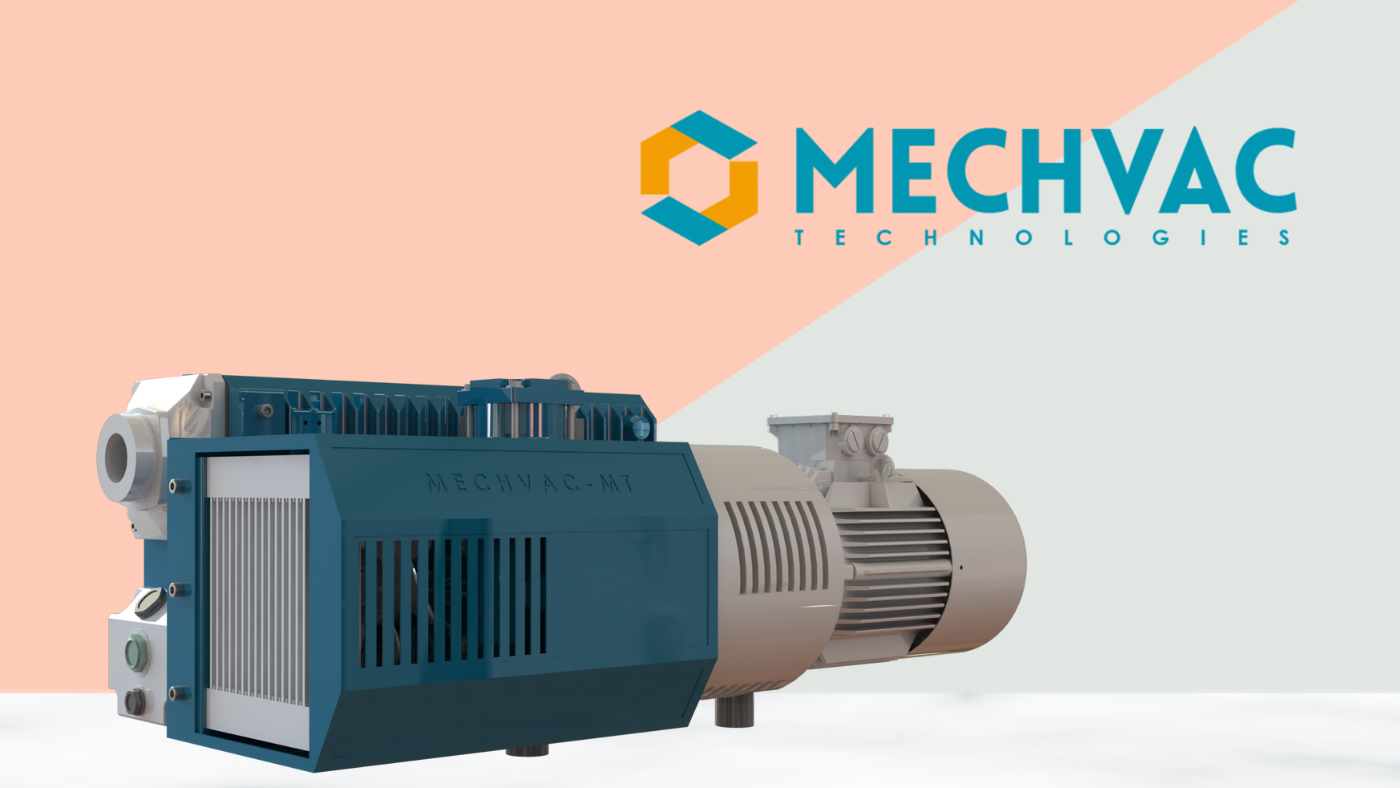

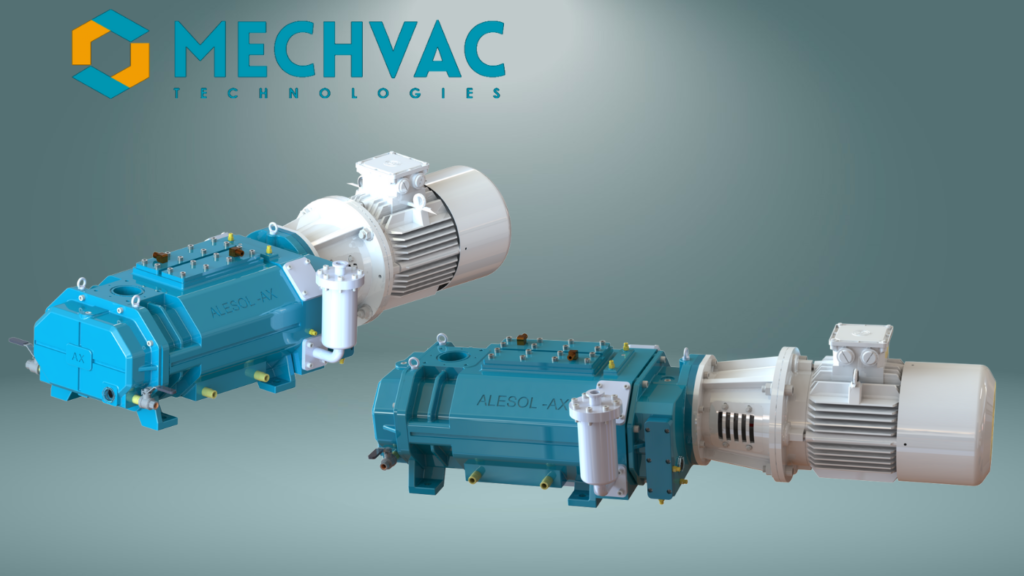

Vacuum pumps help maintain a vacuum within a system, and there are various types available, including dry screw vacuum pumps. Unlike other pumps that rely on oil or water, dry screw vacuum pumps use two screws rotating in opposite directions to compress gas and create a vacuum.

This guide will walk you through the basics of how dry screw vacuum pumps work and their advantages.

How Vacuum Pumps Work: The Basics

Vacuum pumps remove gas molecules from a system to create a low-pressure environment, or “vacuum.” This low-pressure area attracts gas molecules, pulling them out of the system.

Different types of vacuum pumps have unique features, and each serves specific purposes based on its design.

The Inner Workings of Dry Screw Vacuum Pumps

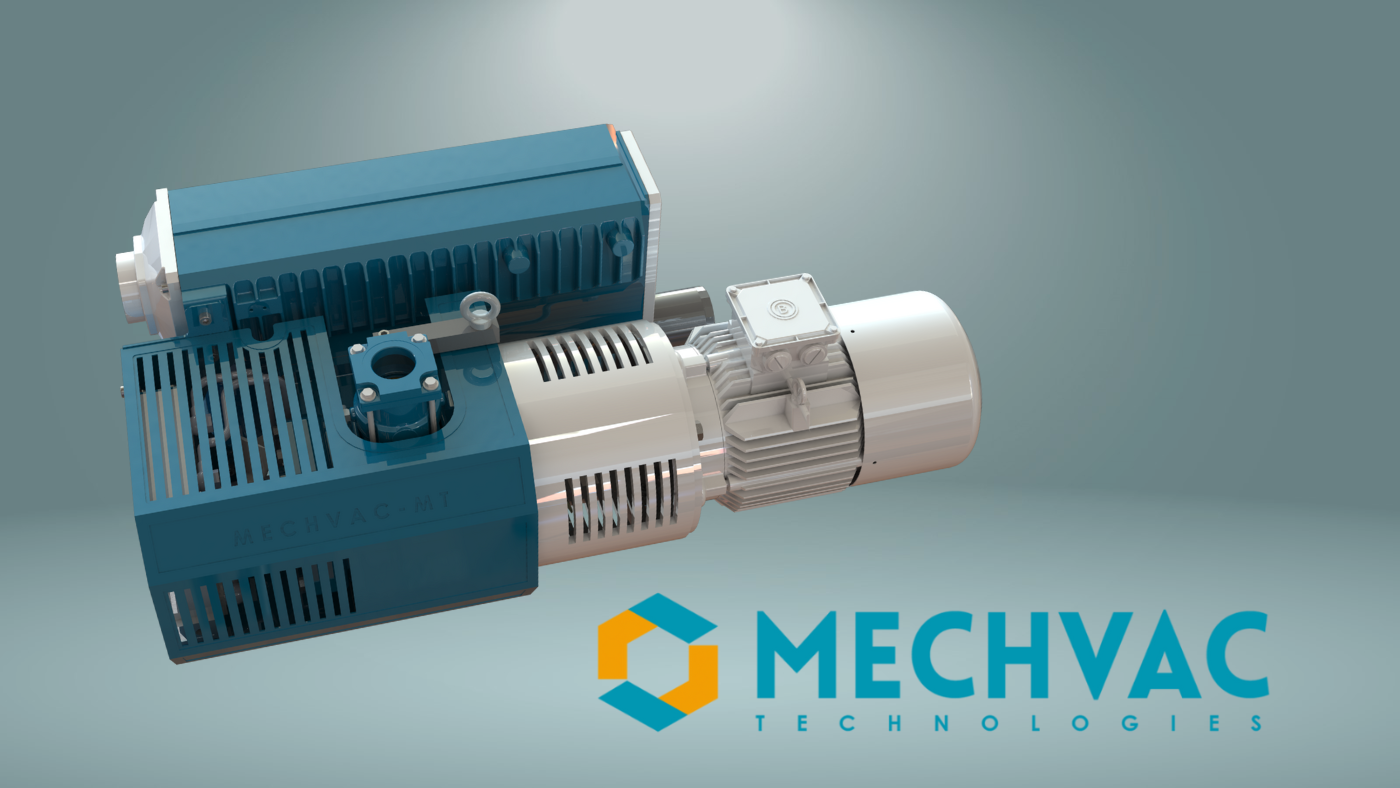

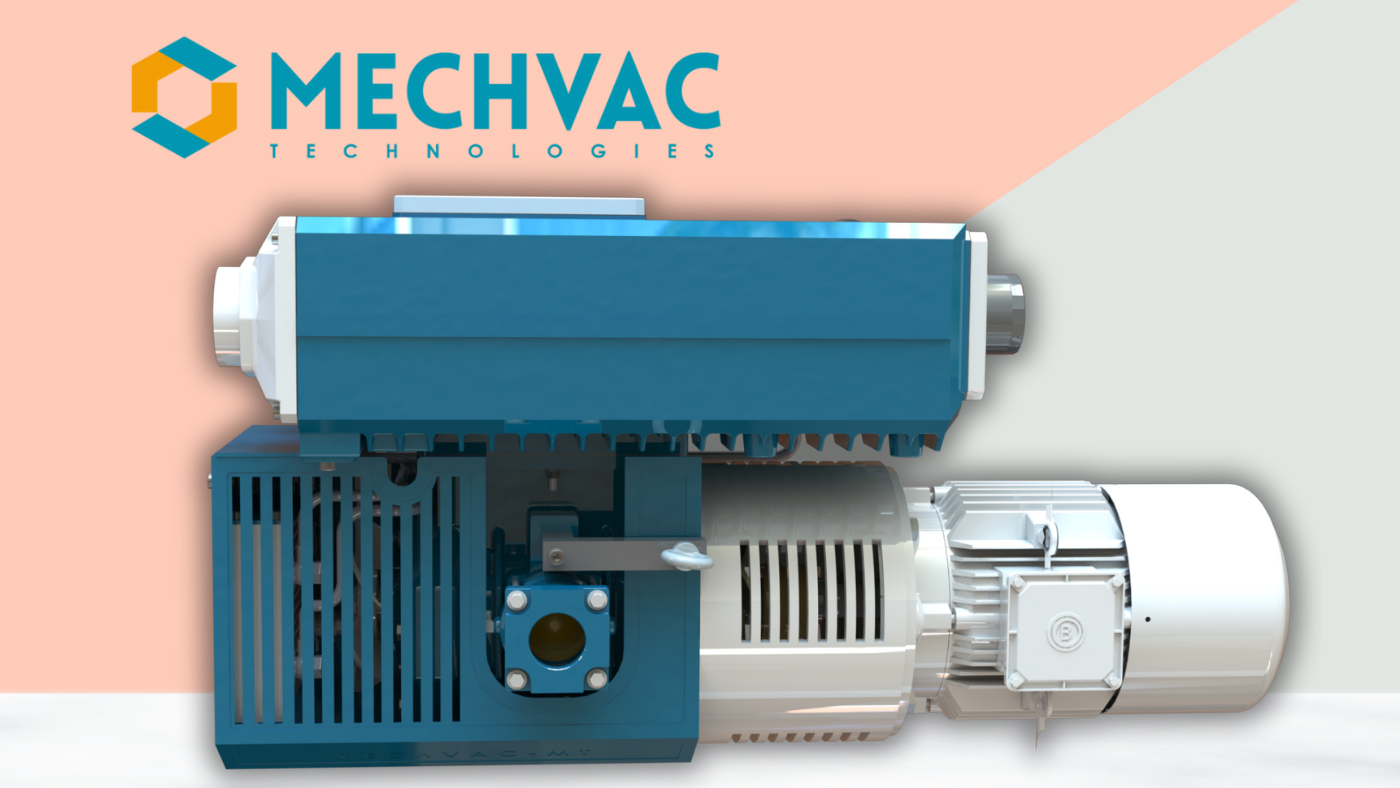

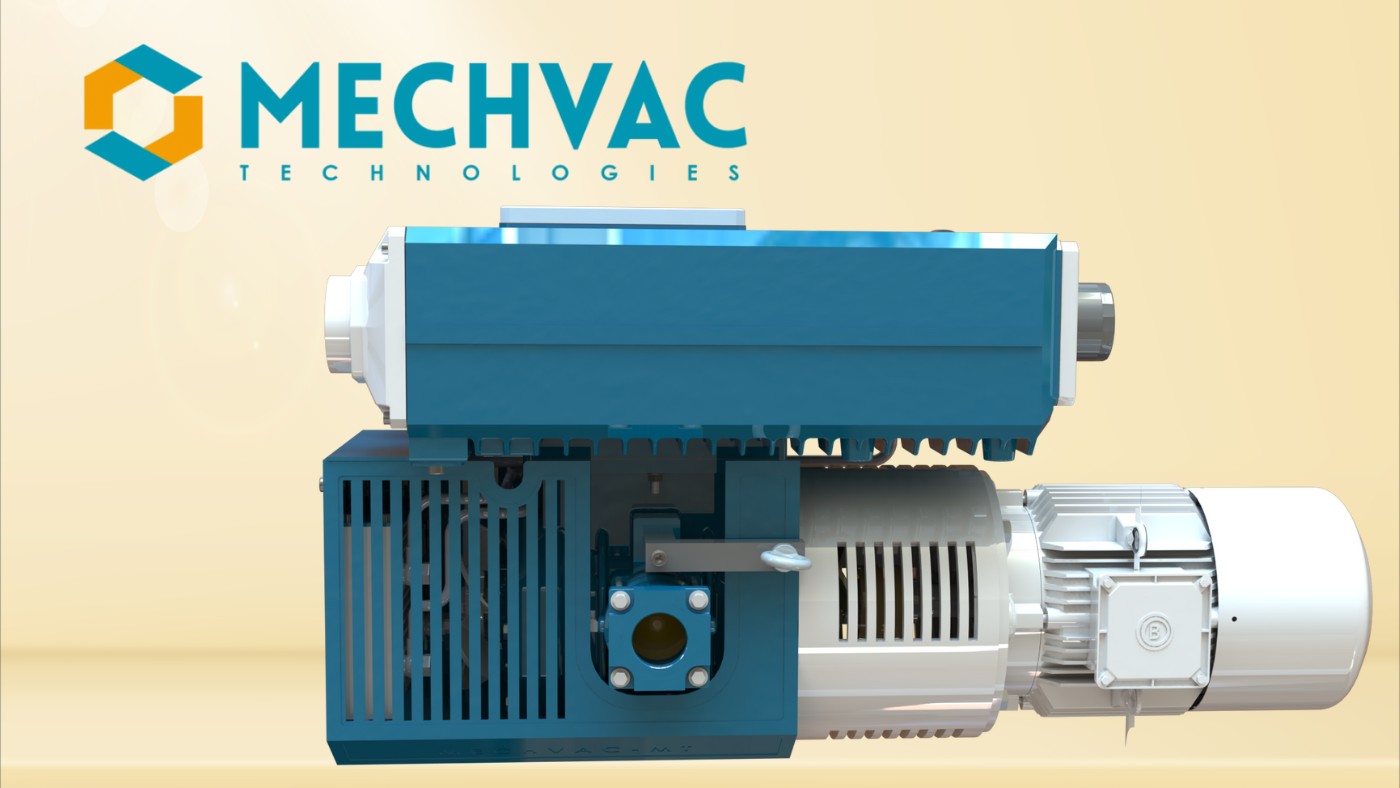

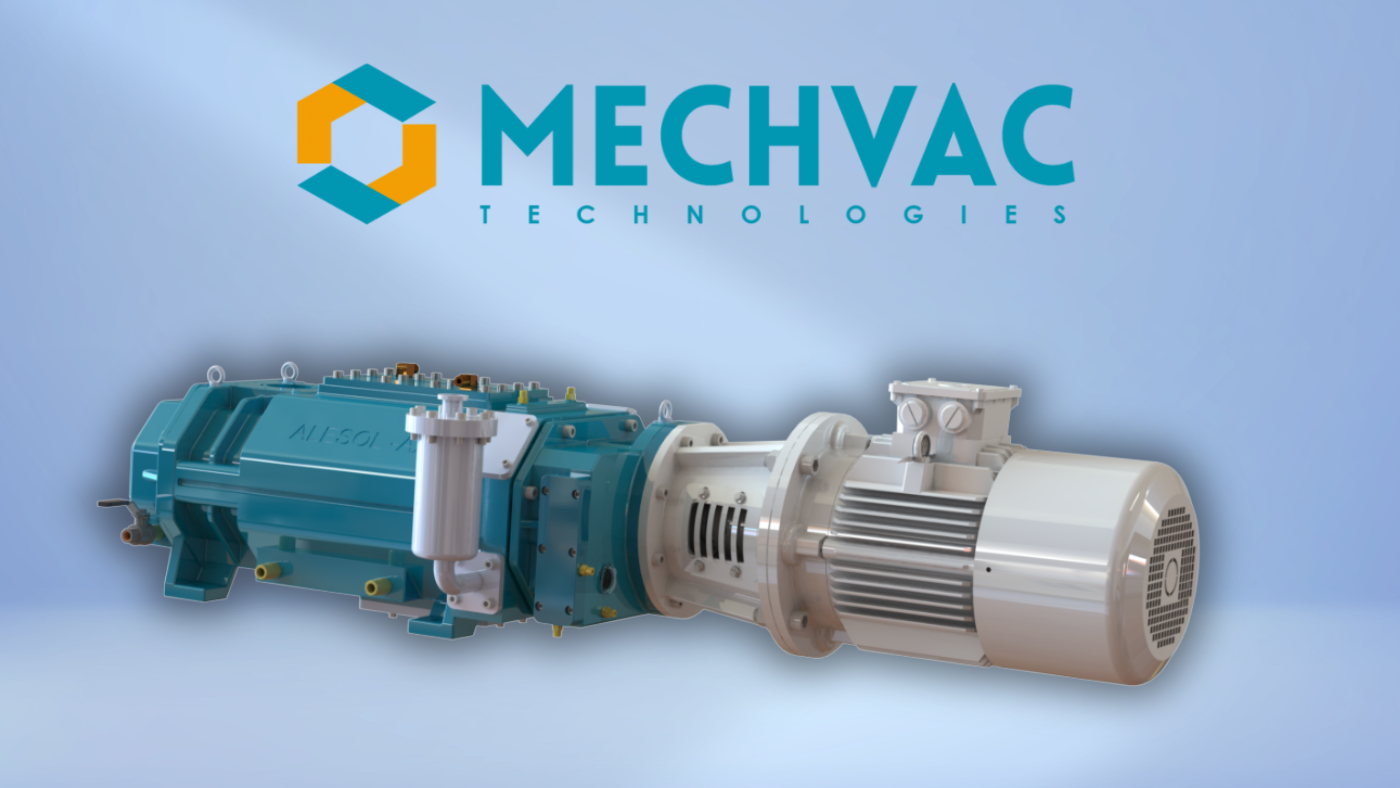

In dry screw vacuum pumps, two screws rotate in opposite directions to compress gas. These screws sit on parallel shafts with a small gap between them.

As they rotate, gas gets trapped in the space between the threads and is moved towards the exhaust end of the pump.

Here, the volume of the gas decreases while the pressure increases, eventually pushing the gas out of the system. Unlike other pumps, dry screw vacuum pumps don’t need oil or water to create a seal, making them ideal for environments sensitive to contamination.

Essential Parts of Dry Screw Vacuum Pumps

While designs may vary, most dry screw vacuum pumps share these key components:

- Screws: The main elements responsible for compressing gas. Typically made from strong materials like stainless steel or ductile iron.

- Housing: The structure surrounding the screws, often made from cast iron or ductile iron, providing a chamber for compression.

- Bearings: Supports for the shafts, made from durable materials like ceramic or tungsten carbide.

- Drive System: Powered by an electric motor, the drive system rotates the screws, ensuring smooth operation.

Advantages and Disadvantages of Dry Screw Vacuum Pumps

Advantages

- Minimal Maintenance: Dry screw pumps need little lubrication, making them suitable for applications where oil or water contamination is an issue.

- Versatile Gas Handling: These pumps can handle a wide range of gases, including corrosive types.

- Energy Efficiency: Dry screw pumps are generally more energy-efficient than other vacuum pump types, which can lead to lower costs over time.

Disadvantages

- Higher Initial Cost: Dry screw vacuum pumps can be pricier than other options.

- Capacity Limitations: They may have a smaller capacity compared to some other vacuum pump types.

Common Uses of Dry Screw Vacuum Pumps

Dry screw vacuum pumps are widely used in industries such as:

- Chemical Processing: To safely remove gases and vapors.

- Food and Beverage: For removing air from packaging, preserving product freshness.

- Medical: Essential for creating vacuums in surgeries and for powering medical equipment.

Innovations and Future Trends in Dry Screw Vacuum Technology

Ongoing research aims to make dry screw vacuum pumps even more efficient, durable, and versatile. Here are a few trends:

- Enhanced Efficiency: New models aim to reduce energy consumption, saving costs.

- Increased Capacity: Larger pumps with higher capacities are being developed for diverse applications.

- Advanced Materials: Materials like ceramics and composites are being explored for better durability and performance.

Key Takeaways

- Reliable and Efficient: Dry screw vacuum pumps use interlocking screws to create a vacuum, with minimal maintenance required.

- Resistant to Contamination: Ideal for environments where oil or water contamination must be avoided.

- Versatile Applications: Widely used across industries, from food processing to medical applications.

- Future-Ready: With ongoing innovations, these pumps are set to become even more efficient and adaptable.

Understanding the basics of dry screw vacuum pumps can help you choose the right solution for your industrial needs. For more detailed information and expert guidance, explore our dry screw vacuum pumps today.